Ford Mustang: Developed with 200-mph Wind Tunnel

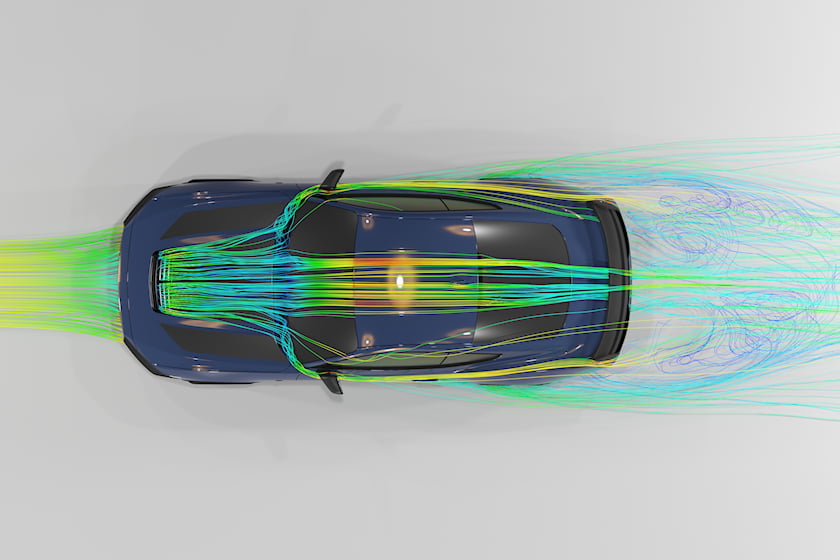

Ford has declared the installation of a brand-new 200-mph Rolling Road Wind Tunnel, applied first in the engineering of the upcoming Ford Mustang Dark Horse for 2024. Of course, it won’t be inactive until that release – instead, the tunnel will be utilized to explore and enhance the aerodynamics of up-and-coming electric, hybrid, and petroleum vehicles.

No doubt, the most profit is observed with cars that have a sporty nature, and Ford maintains that this air-tunnel assisted in crafting the best-downforce 5.0 Mustang to date (available on the Dark Horse with the optional Handling Package). Essentially, this horse-car was designed by Ford like a super vehicle, offering it the potential to be impactful in a large array of motorsports competitions all around the world.

John Toth, North America Wind Tunnels Engineering Supervisor, explains that the rolling road and wind tunnel can simulate wind and road speeds of up to 200 mph, with a capacity of five million cubic feet of air per five seconds – “enough to fill a K-Class blimp”.

Installing this new system allows Ford to gather data with greater accuracy regarding both drag and downforce, leading to increased range and productivity. Furthermore, the tunnel will bring about cost savings in design as well as hasten the launch of fresh cars throughout the design procedure.

“The closer we can get to reality in the lab, the better and faster we can create more energy-efficient vehicles with great on-road and track stability,” stated Toth. “To ensure that we are able to achieve this, testing while the wheels and tires are in motion is essential for improving the aerodynamics of track-ready cars such as the Mustang Dark Horse, which must balance both aerodynamic drag and downforce.”

“We put in around 250 hours in the wind tunnel creating the 2024 Ford Mustang, including Dark Horse,” declared Jonathan Gesek, a program aerodynamicist for the Mustang and Bronco. This culminated in the addition of features such as an optional Gurney flap, strakes near each front wheel to boost underbody downforce, and body parts that guide air to the engine coolers, intake, and brakes.

“The rolling road component of the setup is just as pivotal as the strength of the wind turbine,” stated the engineer. He went on to explain that this particular setup is equipped with a five-belt rolling road “that can imitate genuine drag from the tires.” Every wheel is given its own belt, and a sizable fifth belt runs underneath the center of the vehicle.

Ford’s commitment to growing their business in Dearborn, Michigan through recent technological advancements has proven to be a long-term investment. In a market that necessitates great levels of efficiency due to the emergence of bulky automobiles, Ford is maintaining its advantage over competitors by delivering bigger cars that are still able to conserve energy. This omnicompetent approach ensures the company’s foreseeable future remains positive and prosperous.