Insufficient American Guardrails Cannot Halt 7,000-Pound Pickup Truck.

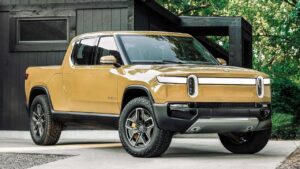

The Rivian R1T has highlighted the dangers of heavy electric cars by plowing through a barrier meant to stop a conventional gasoline-powered vehicle. The testing, carried out by the University of Nebraska-Lincoln (UNL) at the Midwest Roadside Safety Facility (MwRSF), was sponsored by the US Army Engineer Research and Development Center (ERDC) in collaboration with Auburn University’s Transportation Research Institute.During the experiment, the Rivian R1T crashed into a guardrail designed to withstand the impact of a regular car. However, due to its excessive weight, the electric vehicle broke through the barrier, revealing potential safety hazards for such vehicles. UNL and MwRSF researchers noted that the results could have significant implications for the development and regulation of future electric cars.ERDC and Auburn University joined forces to support this innovative research, recognizing the importance of comprehensive safety testing for electric vehicles. With the increasing popularity and production of electric cars, it is necessary to identify potential dangers and address them to ensure the safety of drivers and passengers.After the successful completion of the crash test, the team plans to conduct further studies on different types of barriers and collision scenarios to provide more insight into the performance of electric vehicles in different situations. This research will not only

The examination was carried out to determine if a barrier maintains its efficacy when struck by a 7,000-pound electric truck, and the United States military was interested in ascertaining the readiness of their defensive strategies against hostile vehicles in light of the increasing prevalence of EVs.

It is now glaringly evident, upon viewing the UNL footage below, that the solution is clear.

The UNL reports that a significant number of deaths occur annually due to over 100,000 incidents of run-off crashes involving traffic infrastructure such as guardrails. In the words of Cody Stolle, assistant director of MwRSF, “There is a pressing need to tackle this problem.” Stolle also notes that as the number of electric vehicles (EVs) on the road rises, the percentage of run-off-road crashes involving EVs will also increase.

It should be noted that the barrier railing was created with the intention of reducing the impact of collisions. Its main function is to redirect a car away from potentially dangerous surroundings, such as a steep cliff or a dense forest. Additionally, it aids in reducing the speed of the vehicle. As depicted in the video below, the standardized guardrail by the Federal Highway Administration failed to effectively deflect the intense impact of an R1T traveling at 60 miles per hour.

The barrier under scrutiny consisted of a 12-gauge fluted metal, fastened onto sturdy steel columns that were six inches deep and fortified by eight to 12-inch blackout screws. Standing at a height of 31 inches, it effectively halts the movement of standard trucks such as the Ford F-150 with conventional internal combustion engines.

After successfully completing the world’s first crash test, plans for additional crash tests are now in the works. Once these tests are completed, all parties involved will come together to discuss future actions. According to Genevieve Pezzola, a research civil engineer at ERDC, “The US Army Corps of Engineers’ mission is to work with our partners to provide crucial engineering solutions that will safeguard our nation, boost our economy, and minimize disaster risks.” She also emphasized the importance of conducting EV baseline comparison tests to identify any potential threats to our country. This initial step is crucial in ensuring that our nation’s protective measures, such as roadside barriers and barriers against hostile vehicles, are able to adapt to the changing vehicle landscape.

As the demand for electric vehicles (EVs) continues to rise and the Tesla Model Y maintains its position as the top-selling car globally, the scenario is expected to escalate further.

According to the latest research from the MwRSF, there is no discernible variation in the frequency of run-off crashes between electric vehicles (EVs) and internal combustion engine (ICE) vehicles. However, what sets EVs apart is their weight, which can be up to 20-50% heavier than traditional ICE vehicles. This translates to a significant increase in energy upon impact.In light of these findings, Stolle, a researcher at MwRSF, emphasizes the importance of reassessing the designs of roadside barriers not just for EVs, but for all vehicles. He stresses that this is a crucial and pressing matter that requires immediate attention.

The topic of heavy electric vehicles (EVs) and their impact on road safety is not a new one. As early as 2022, the renowned Insurance Institute for Highway Safety (IIHS) began developing guidelines for their rigorous testing process in anticipation of the rise of heavy EVs. However, less than a year later, the IIHS made a concerning statement urging for reduced speed limits due to the alarming potential for destruction caused by these vehicles.

The R1T is facing potential harm to its reputation in this situation, although it should be noted that the GMC Hummer EV has a weight of 9,500 lbs and can achieve a 60 mph speed in just three seconds. However, these vehicles are solely powered by electricity, making the contrast most evident when comparing them to the gas-operated Ford F-150 and its electric counterpart, the F-150 Lightning.

The heaviest weight for a Ford F-150 in Platinum configuration is recorded as 5,038 lbs, whereas the Lightning version in identical trim measures at a hefty 6,893 lbs.A fully outfitted Platinum option of the Ford F-150 has a maximum weight of 5,038 pounds, but the Lightning iteration with the same trim level carries a significantly higher mass of 6,893 pounds.