Toyota Factory: 60 Years of History

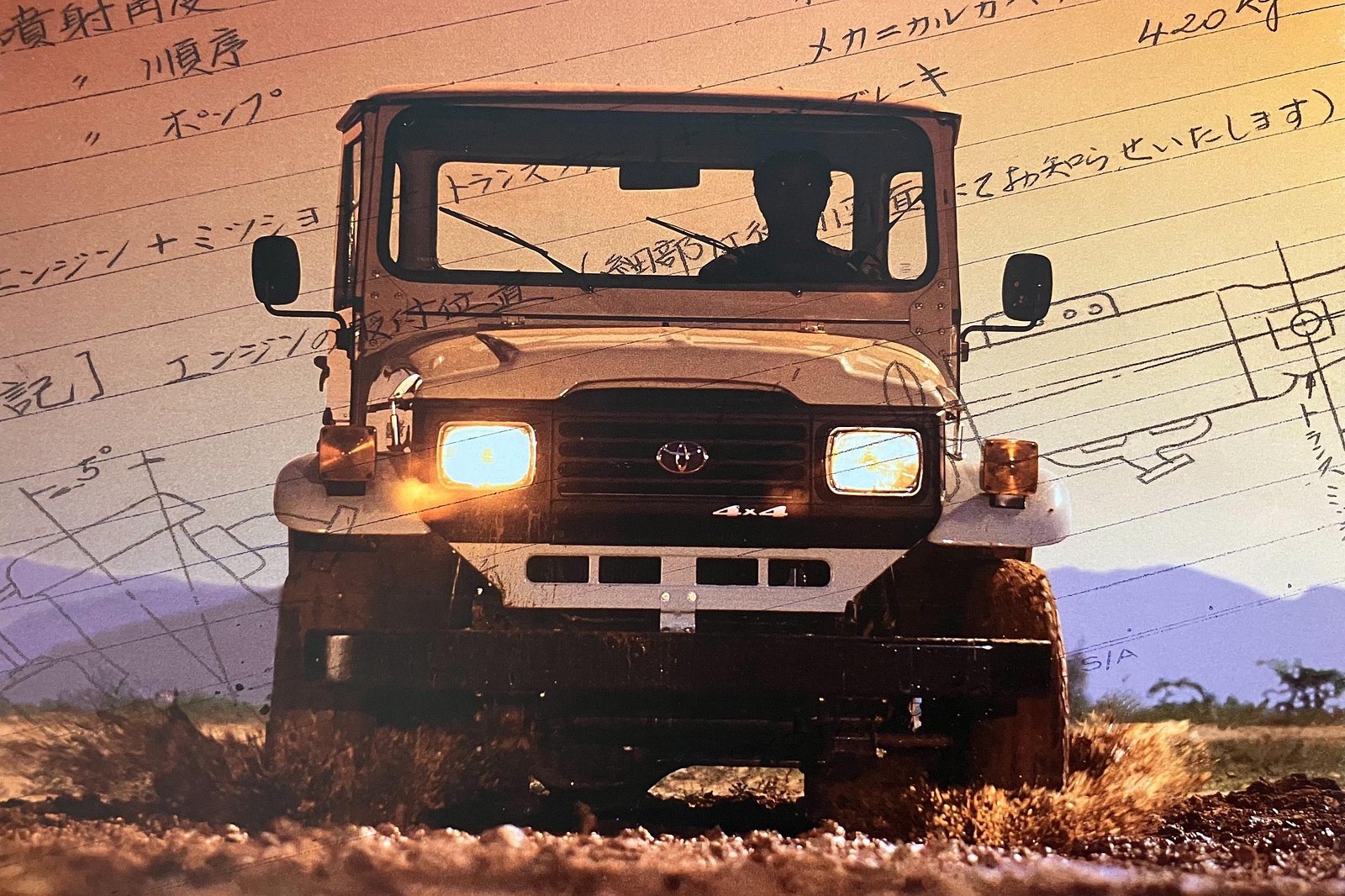

Toyota has concluded the operations of its inaugural factory constructed outside Japan. São Bernardo, Brazil’s plant, which had been operational for 60 years and supplied more than 100,000 Toyota Bandeirantes – a FJ40 Land Cruiser fitted with a Mercedes engine – has been shut down.

Since the turn of the millennium, the factory has been focused around producing components, yet it will always remain connected to the Bandeirante; a J40 Land Cruiser furnished with a Mercedes-Benz OM-364 engine. Driven by a normally aspirated four-cylinder diesel motor, the off-roader was little more than plodding and sluggish – something that Brazil needed that time due to its high desire for resilient agricultural vehicles.

In the year 1994, the Sao Bernardo production center persisted in producing Banderantes, whereas the majority of the world had shifted to more lavish Land Cruisers such as the Land Cruiser 70. That same yr; it eventually got the Toyota 3.7-liter inline-four diesel, and continuing in this fashion till 2001.

Clearly, Toyota has a deep affiliation with the Brazilian people. It has maintained a respectable portion of the market, comprising about nine percent; however, GM and Stellantis have since taken the lead, manufacturing vehicles in the South American territory. Even though one factory was shuttered by Toyota, they will still keep producing cars in Brazil.

“The history of production at the Sao Bernardo factory is coming to an end, however, we are looking ahead to the future,” remarked Masahiro Inoue, General Manager of the Latin America Division, at the factory’s closing ceremony. “With the employees and their families who have relocated (due to the production transfer), Toyota will make even better vehicles and boost exports to Central and South America. We will be a part of furthering the growth of the Brazilian automotive industry.”

One wonders why Toyota selected Brazil in the first place. It was established back in 1938 that their initial factory was founded, then a further 19 years would pass before another facility was set up. To those well-versed in history, this situation may be understandable. Alternatively, an even more extraordinary outcome materialized when just three years later it had achieved yet another production unit.

The primary motive for Brazil’s demand was that it was thriving economically, thus requiring strong vehicles. There is also speculation that there are more Japanese immigrants in Brazil than other countries, though this has never been confirmed.

Rather than just investing in their native Japan while shipping out cars to Brazil, Toyota wisely heeded the Automotive Promotion Law Based on Domestic Production decreed by the Brazilian government. This law effectively banned the import of cars into the country and made it mandatory for foreign automotive companies to set up shop domestically if they wished to make profit in the emerging market. As a result, Toyota Brazil was established in 1958 with much success afterwards.

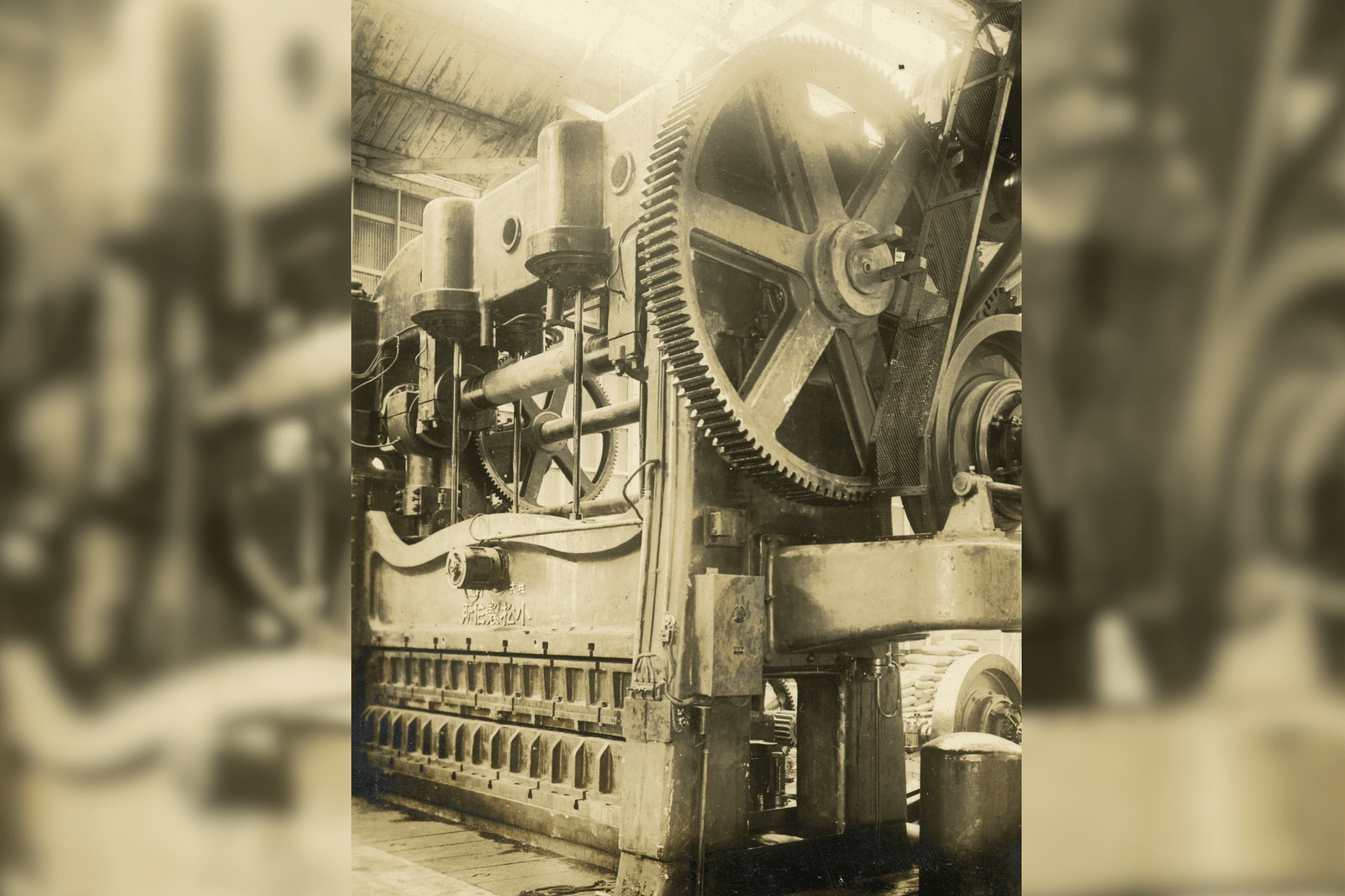

Throughout its history, the terms and conditions of the Toyota Investment in Brazil (IRA) fluctuated considerably. Beginning with an initial local manufacturing level of 60%, the Japanese automaker eventually increased this percentage to 100%. Interestingly, the giant press machine which had been shipped over from Japan for use in the Brazilian plant is now being returned after having become surplus to requirements. We can only assume that this will eventually take pride of place in the Toyota City museum.

Desirability has always been key in the automotive world, and this is something that Akio Toyoda sought to capitalize upon. His vision of shuttering the factory came when Toyota had reached unprecedented heights with their range of cars – including dynamic sports cars like the GR86 and GR Corolla, plus more ordinary rides like the popular Prius, Grand Highlander, and the recently released Land Cruiser. These models have already enjoyed remarkable success, further illustrating the power of Toyoda’s vision.

Akio described his choice to shut down Sao Bernardo as “a painful decision that cannot be expressed in words.” He went on to explain that the closure was necessary due to a variety of factors, including financial pressures and a changing market. Despite the difficult nature of the decision, Akio was adamant that it was the right one for the company. He said that the company had done its best to ensure that all employees were provided with the necessary support and assistance during this transition. Akio concluded by expressing his deep regret and sorrow for having to make such a tough call.

What about the employees? Toyota is making a big effort to offer Sao Bernardo staff the possibility of working at any of the other three industries in Brazil. With that being said, the closet factory is around one hundred miles distant, yet some personnel are too aged to relocate, and certain individuals don’t desire to.

Remnants of the factories still remain, building variants of Corolla Cross, Corolla Sedan, and Yaris explicitly meant for South American buyers. These designs are distinct from those found in other parts of the world.

The plant of Sao Bernardo is no more required, as its previous role was simply focused on fabricating components for the Hilux and Corolla. With the imminent arrival of an all-new Hilux being even closer to the Tacoma than before, it seems that its production may be taken up by the American and Mexican factories of the Taco. Other plants are able to assemble these parts sufficiently, rendering the former service superfluous.

Hi there, just became aware of your blog through Google, and found that it is truly informative.

I’m gonna watch out for brussels. I will appreciate if you continue this in future.

Numerous people will be benefited from your writing.

Cheers! Lista escape roomów

I like this web blog very much, Its a real nice berth to read and

incur info.!