Crafting Luxury Automobiles from Start to Finish

As the automotive industry strives to optimize its roboticized production and minimize costs, only a few remaining automakers still practice manual techniques. Despite this, these brands often remain some of the most luxurious and highly sought-after, with Bugatti as one exemplary representation of an engineering masterpiece. Proudly displaying their intricate processes in the making of their Chiron and sister models, Bugatti recently released a press statement outlining the painting procedure utilized.

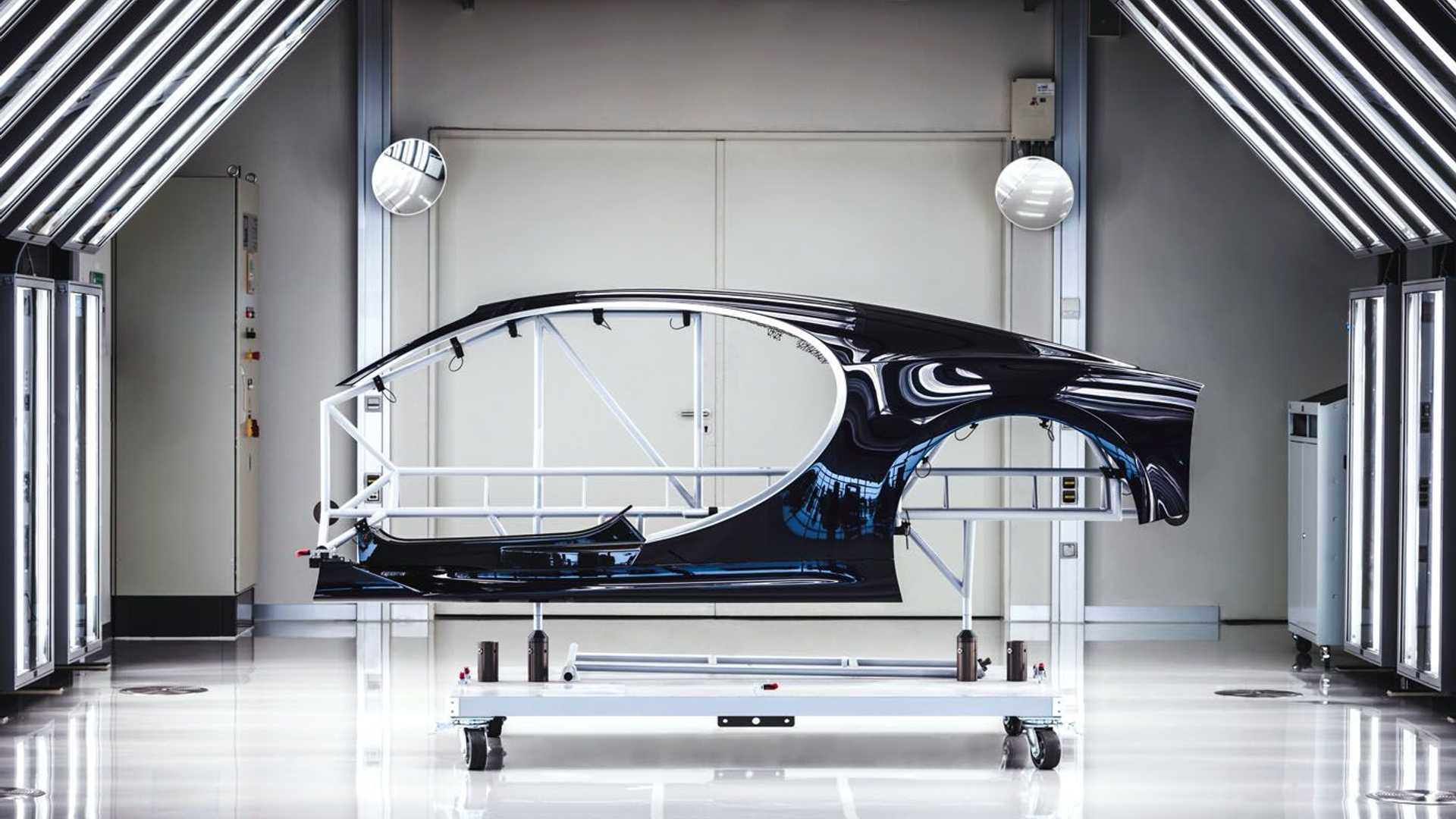

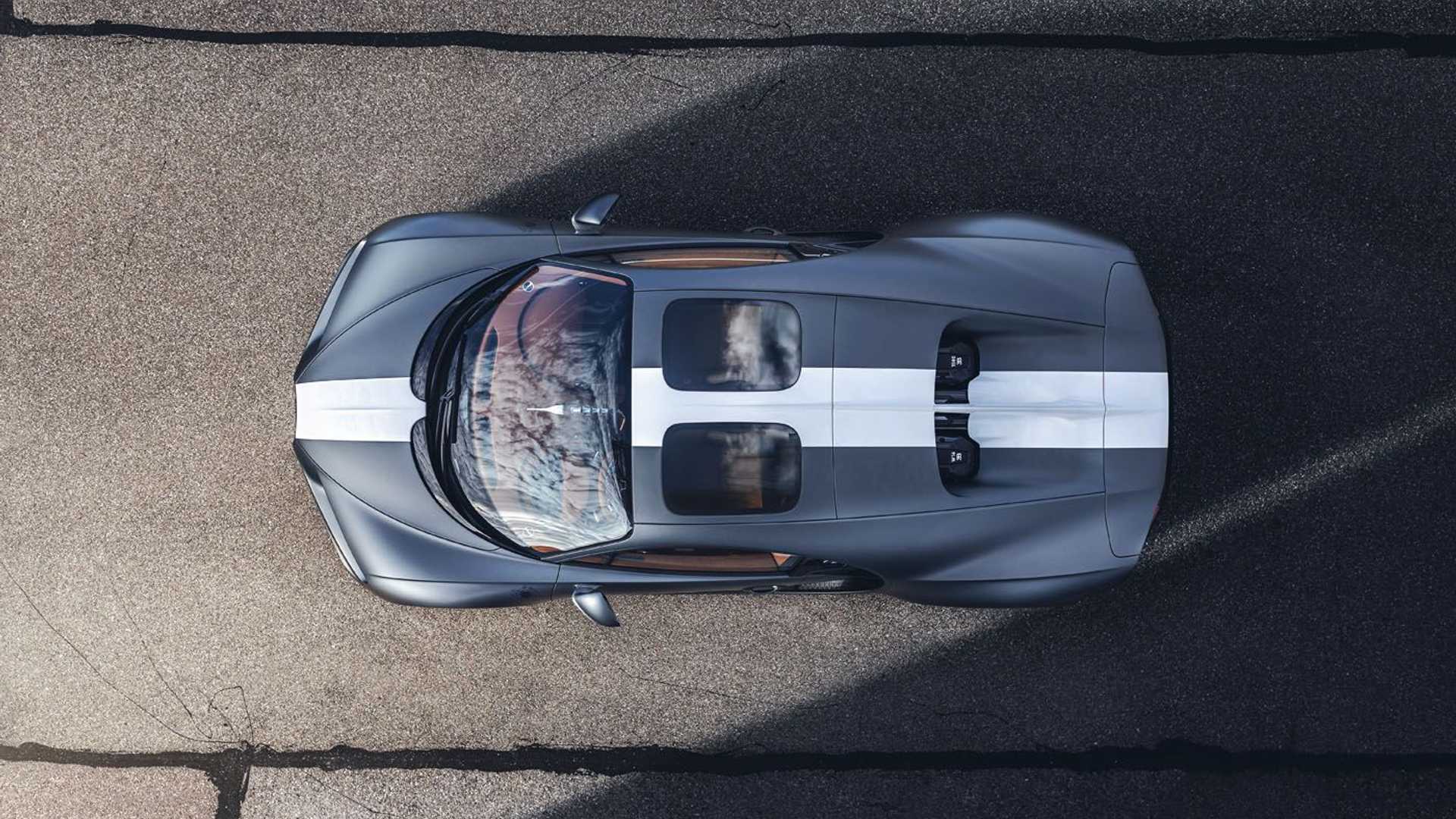

In total, it takes an estimated 600 hours for each Bugatti’s Molsheim factory-made car to be carefully painted. Interestingly enough, four to five cars would be created by a typical non-high volume luxury car manufacturer during the same time period. A special step in the assembly of a Bugatti is that every piece must be individually painted prior to installation onto the actual vehicle, allowing for every region to receive superb attention and a flawless finish. This extra level of detail isn’t typically found in mass-manufacturing auto companies.

Despite the fact that we’ve showed you many other painting clips, what needs to be done before one applies the initial coating of paint, clear coat, or primer is far more thorough. Specifically, small blemishes require a careful inspection, which doesn’t just involve any automated process – it’s just the workers’ judgment and their dexterous fingertips. Until lastly, two layers of primer are put on with fine-gauge sanding interspersed.

In excess of 100 hours is devoted to the preliminary preparation of each vehicle. Nonetheless, despite these efforts, the exterior components are far from ready to be coated in paint – hence commences an endlessly revolving cycle of further clear coating, followed by sanding, and yet more clear coating before another period of sanding. Bugatti describes this meticulous revision as “a labor of love, consistently aware, persistently applied, and lovingly polished”. Before the finishing touches can be done on the various parts, they must all pass the test of perfect surfaces set by the experts. However, even when that is achieved, it still isn’t time for the actual painting process to begin.

The team then scrutinizes every singular section thoroughly, since different types of materiel are applied to the chassis, each with its special coating requirements. Even if a single discrepancy in shades between two components is evident, a repaint is demanded. And when the automobile is entirely sprayed to a perfect finish, nearly 4 more days are devoted to polishing, which Bugatti declares that this is the most laborious refining operation in the industry. In conclusion, such activity goes from beginning to end within the range of 600-700 hours for painting a latest Bugatti.

Ettore Bugatti was someone that wholeheartedly embraced the beauty of engineering when it came to cars. Raised in a family of artists, Ettore visualized the automobile as an art form well before they were commonly considered as such. This ideology carries on even today at Bugatti, ensuring that each facet of design and manufacturing is produced with a commitment to top-notch aesthetics; an attitude that surely applies to our paints, attests Christophe Piochon – President of Bugatti – about the laborious painting approach.

Source: Bugatti