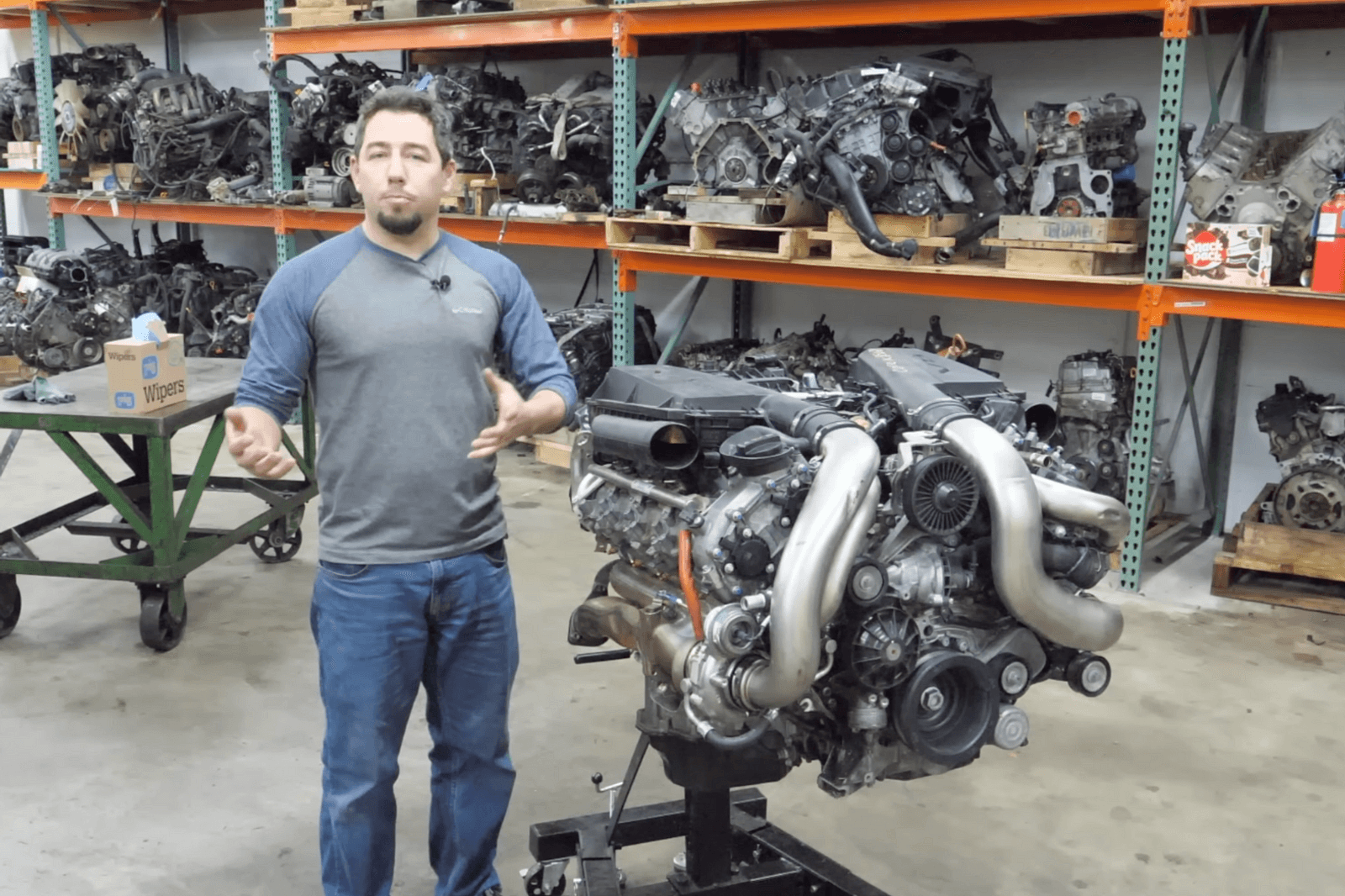

M278 4.7L Bi-Turbo V8 Engine

Without regular upkeep, dire effects will be noticed on any motor, as witnessed by Eric from I Do Cars when he heavily dismantled a non-functioning Mercedes-Benz V8.

Eric acquired the earlier 4.7-liter twin-turbocharged M278 V8 engine, a predecessor of the M178 motor housed in the Mercedes-AMG GT. Generating well over 400 horsepower, this expensive V8 was procured from a 2013 ML 500 – now identified as the GLE-Class.

Not numerous particulars were known regarding the motor, including miles per gallon. There was not much of an indication of too much heat at first sight. In any case, when Eric clung to the crank to assess if the motor was secured up, he required more energy, signifying that the problem could plausibly be found in its internal workings.

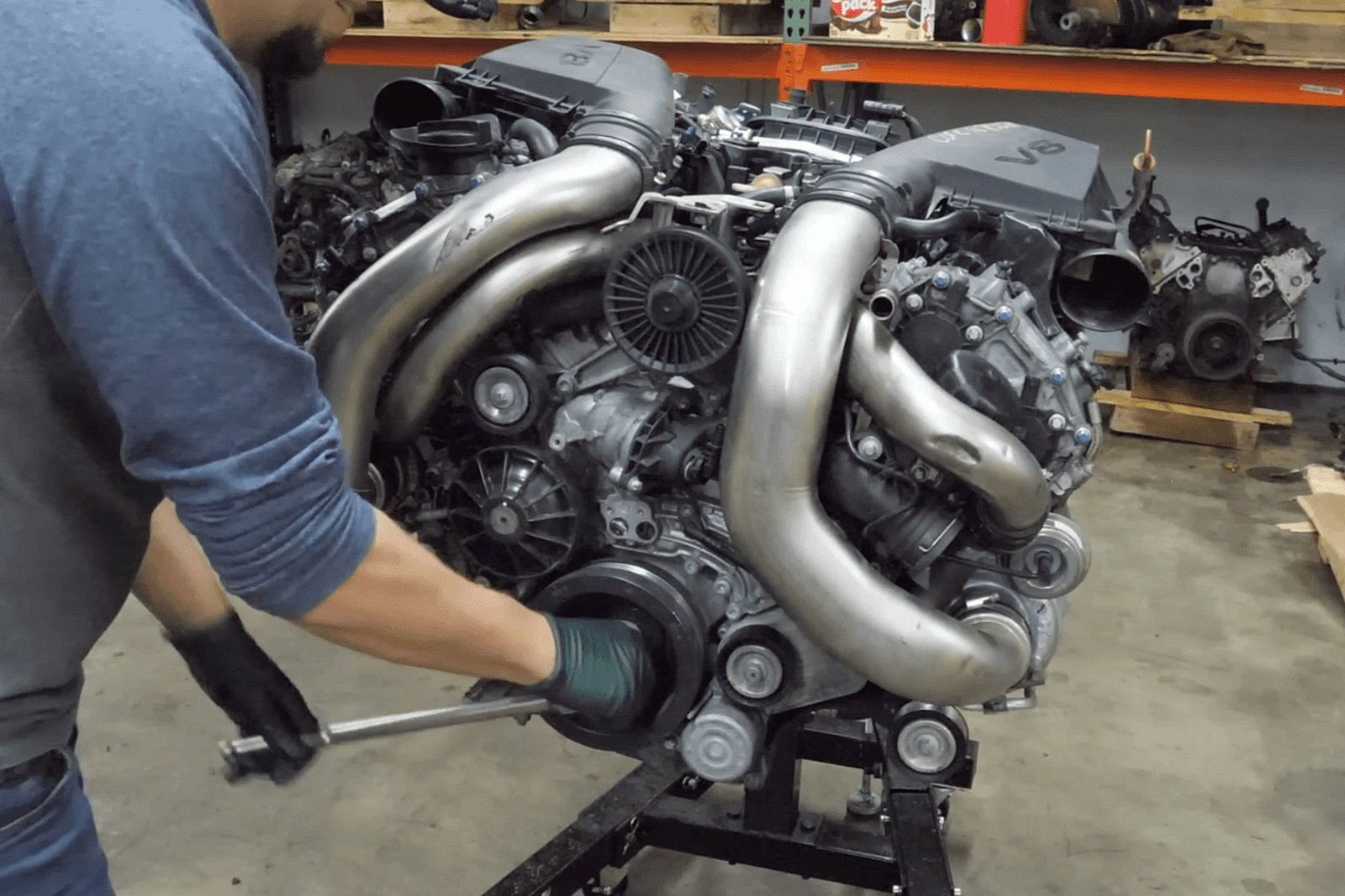

Once Eric had taken away the air boxes, high-pressure fuel lines, and intake manifold, he was shocked by what he saw at the back of the valves – they were, in his words, “some of the crudest intake valves” he had ever come across. Luckily, the Honeywell turbochargers were both in great shape.

The mechanic got to work, beginning with taking off the forced induction system. After that was out of the way, the valve cover had to be removed from the engine. Observing the substantial pieces of the camshaft assembly, only minor damage to some parts was visible. The remaining portion appeared to be in better condition.He went to work, starting by detaching the supercharged system. Subsequently, he detached the valve lid from the motor. He inspected the vital elements of the camshaft build-up and there was only slight destruction to some components. On the contrary, the other half seemed in a more advantageous state.

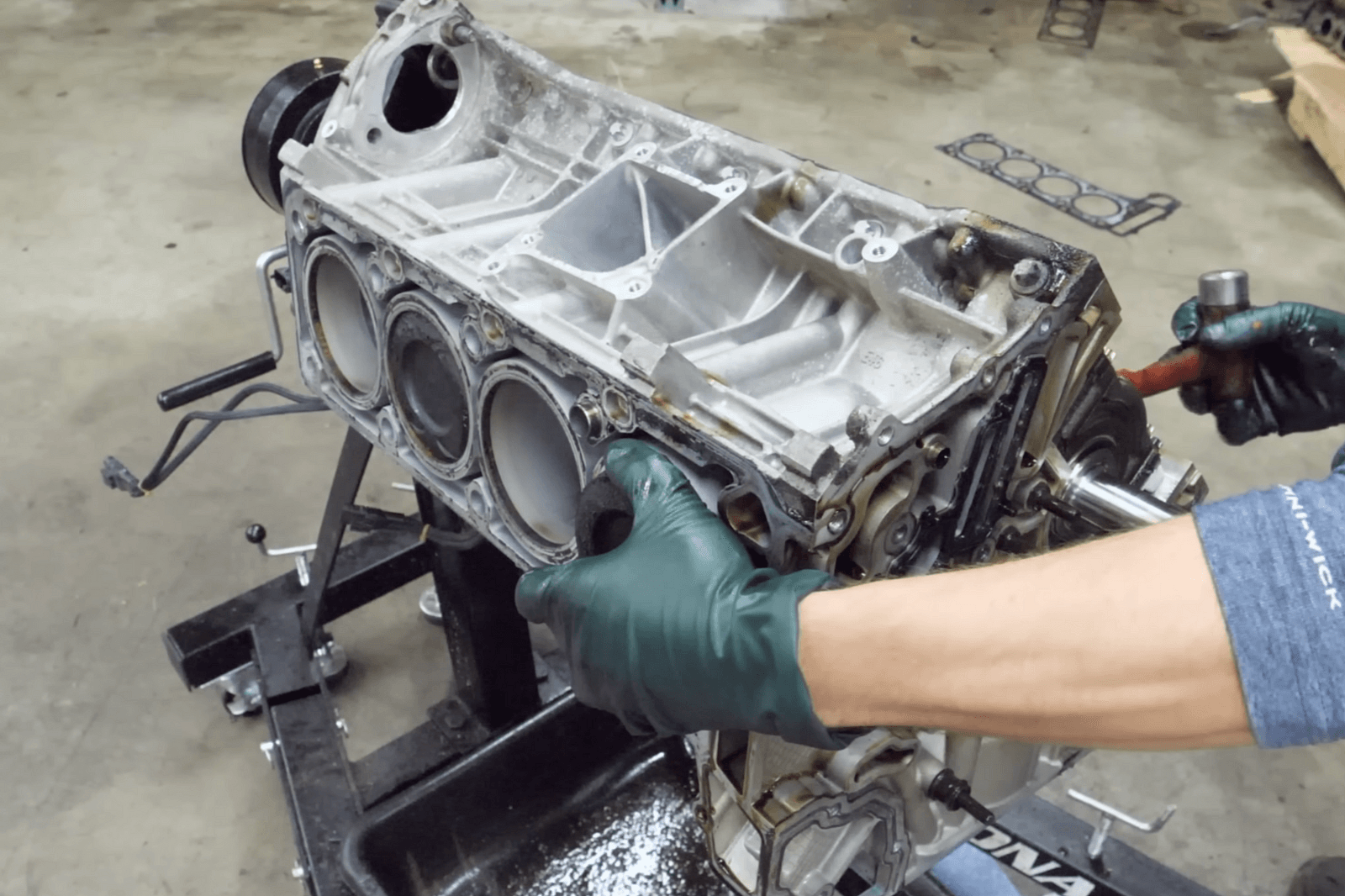

Prior to detaching the camshafts, Eric eliminated the oil filter containing a leaf and a few fragments of metal. We do not know how they ended up there, but the camshafts and their journals gave no indication of possible damage. By taking out them, it enabled separation of the cylinder head from the engine block.

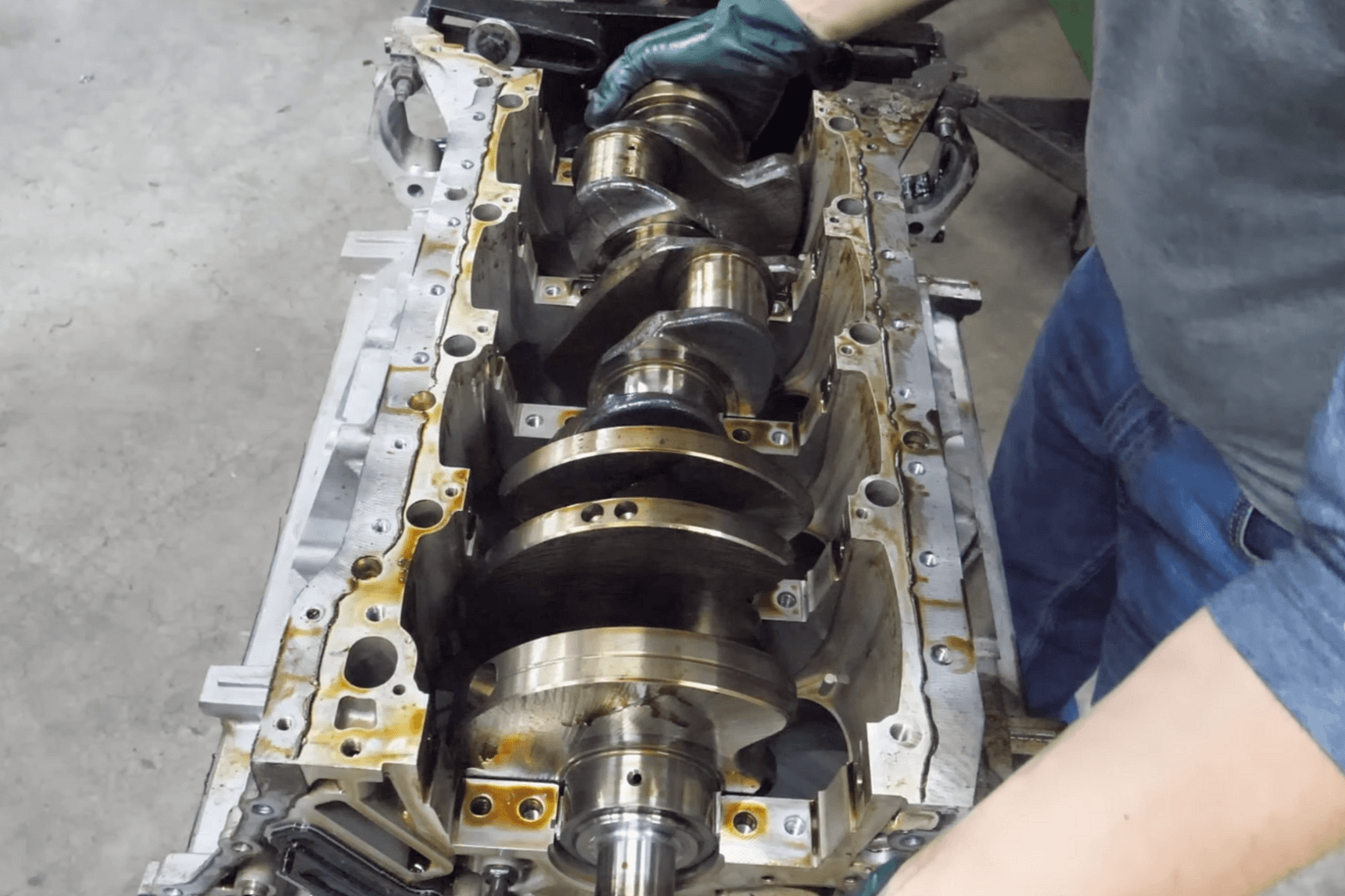

Eric uncovered the major difficulty here, seeing that the cylinders had inferior bore ratings. He then extracted the oil pan, synchronization components, crankshaft assortments, and pistons; however, the parts appeared restorable. Looking at the substantial scores on the cylinder linings, the harm to certain pistons skirts was predictable.

Eric deduced that the possessor could have been running the engine too intensely for an extensive term, enlarging the pistons which harmed the barrel walls. The problem is due to human ineptitude and not definitely inferior engineering. As regularly happens, a usual lubrication transformation together with some machine civility might have preserved this V8 generating set.

Your expertise on this subject shines through in this post.