Reach 10,000 rpm With Low Power Loss

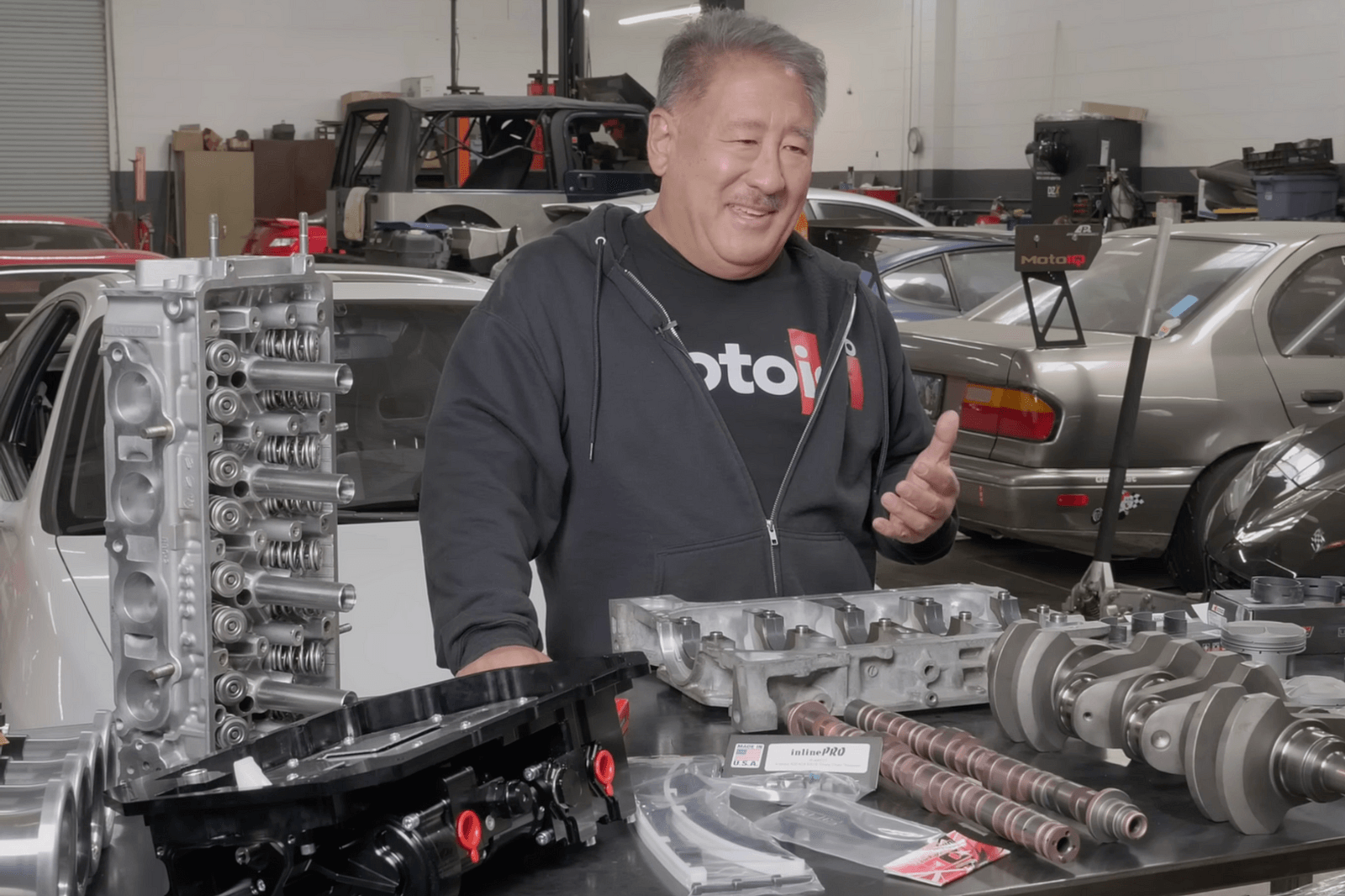

The Honda K-Series is distinguishable for its known dependability, similar to that of the Toyota 2JZ and GM LS V8. That being said, MotoIQ’s Mike opted for the engine for a patron who was seeking a non-turbocharged power unit that can spin up to 10,000 rpm.

The base mill is the K24, which has been included in Honda Accords and CR-Vs during the past two decades. Well-known for their capability to rev high, the K 24 can be taken up to an impressive over 10,000 rpm redline with certain modifications – even matching some of the highest-revving engines around. However, often times such modifications come at the cost of power, something Mike wants to avert with his latest project.

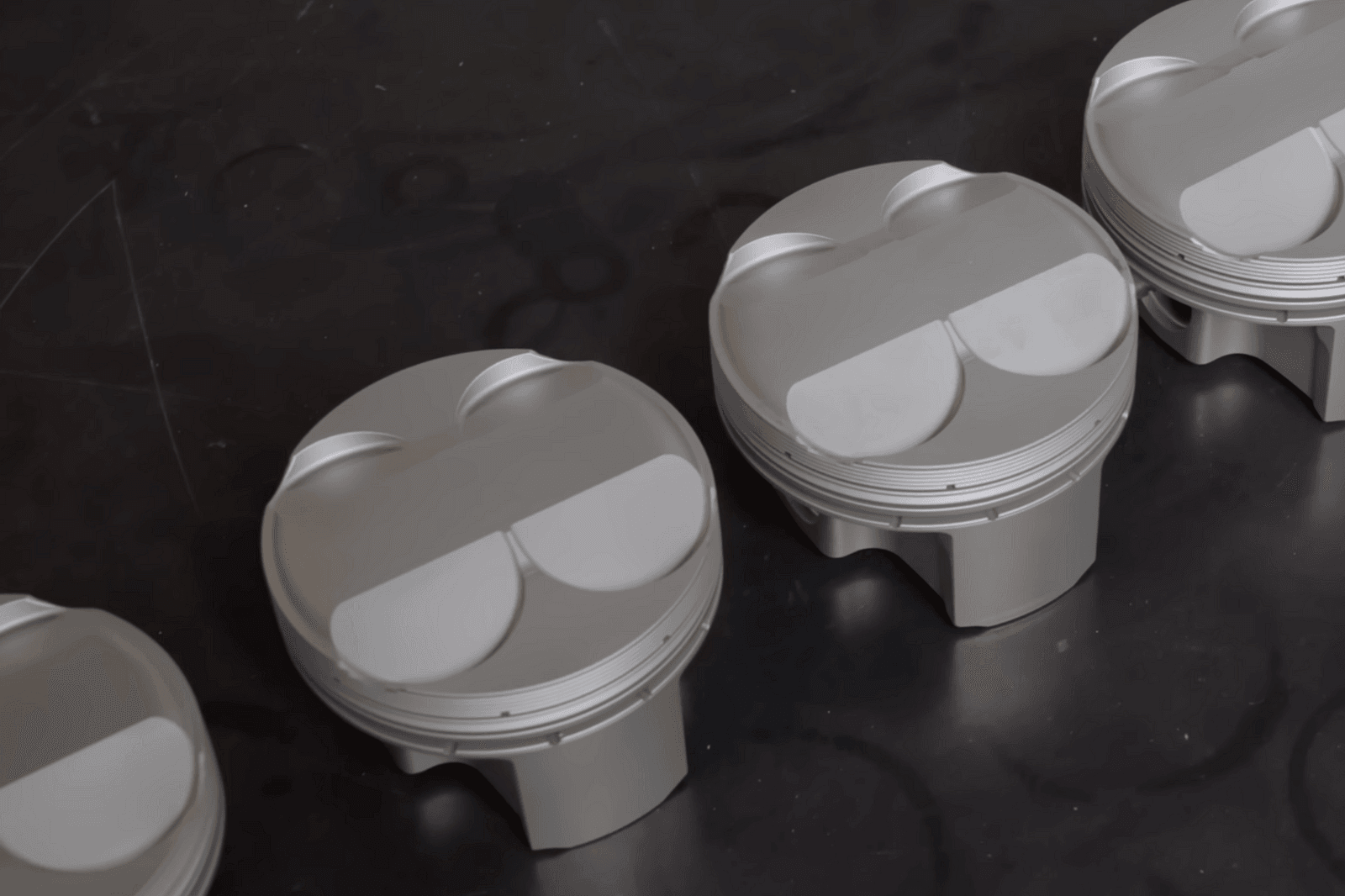

In the effort of achieving this ambition, a number of new components are needed, like a crankshaft manufactured from aerospace-grade 4340 billet steel courtesy of ZRP. This assembly will be linked to pistons created by JE Pistons with a collection of extended rods produced by Eagle (anti-stocking 1.53 rods to upgrade the ratio to 1.63).

An alteration in the dimensions will lessen piston velocity at Top Dead Centre (TDC), leading to a heightened volumetric and thermal effectiveness. The rods, comprised of 4340 steel, are coupled up with ARP 625 Custom Age rod bolts. To pursue a goal of 10,000 rpm, JE apropos of thicker walled piston pins, which imbue additional heft but whose inclusion enhances dependability.

In regards to the piston rings, the primary one is of steel construction while the secondary ring is made from iron – both at a width of 1.1mm. As for the oil rings, they are slim and have minimal tension. Mike selected tri-metal bearings from King Racing in addition to an harmonic balancer from Fluidampr.

Transitioning to the cylinder head, this K24 engine build has a Drag Cartel CNC machined head, providing enlarged ports and improved short side radius.

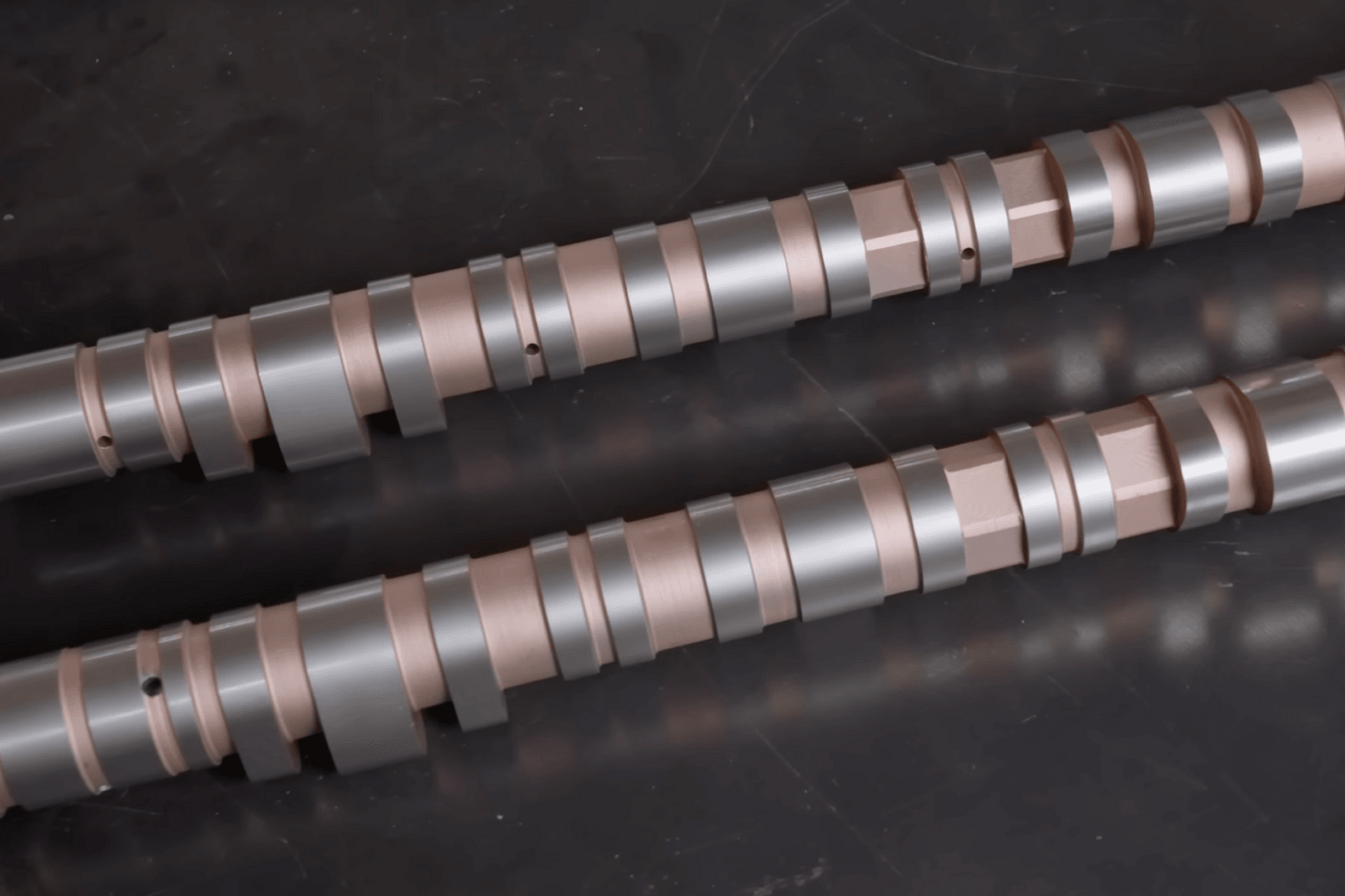

The camshaft (featuring the utilization of VTEC), on its own throttle bodies, along with its timing assembly components all arrive from Drag Cartel. In regards to the intake and exhaust valves, keepers, and springs they each hail from Supertech.

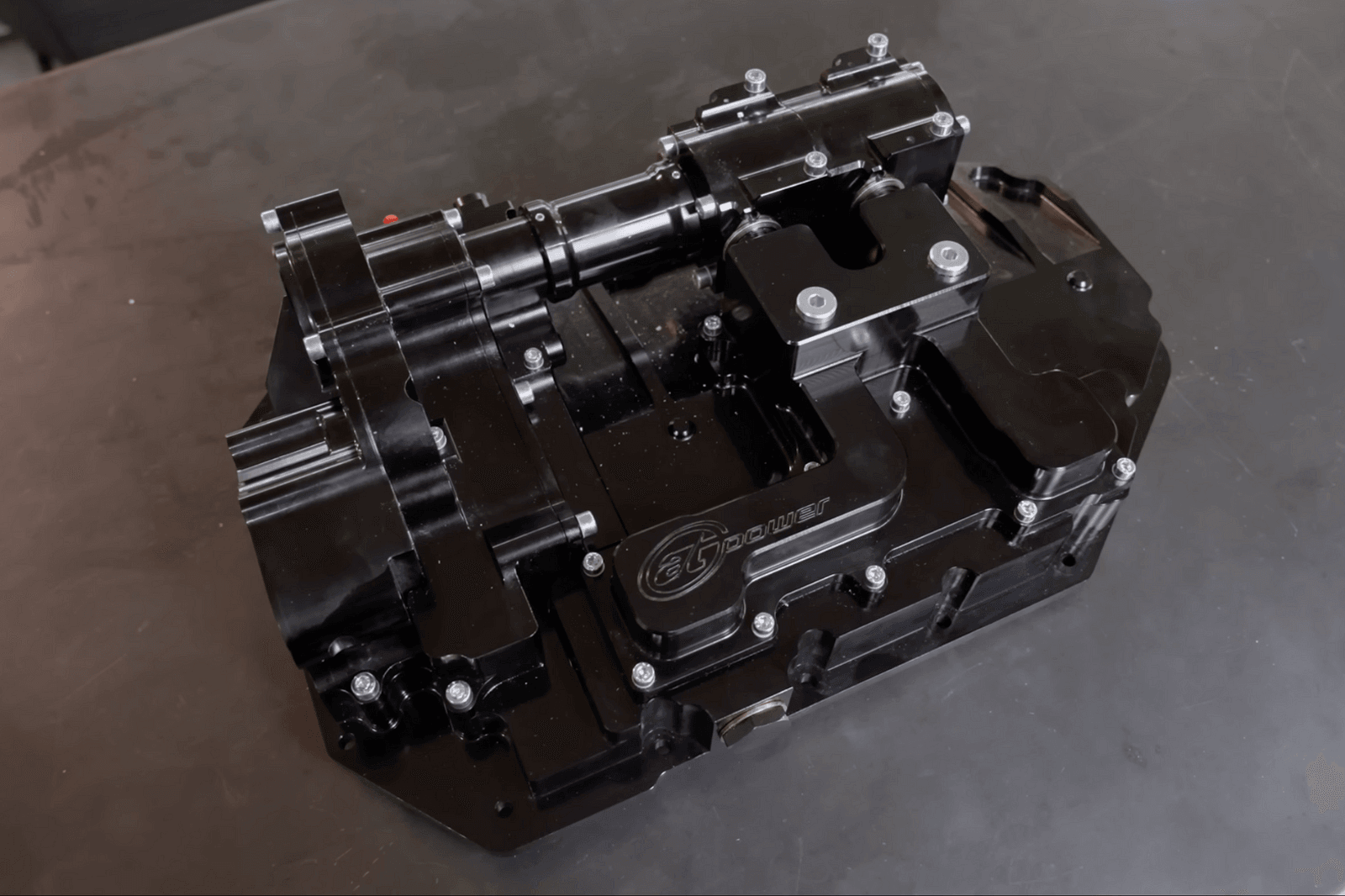

In high revving engine builds, employing a dry sump oil system is always an ideal choice to ensure that oil pressure remains steady, and oil starvation can be avoided when it matters most. This particular setup was supplied by AT Power’s organization in the UK.

In progress, once completed, the K24 will have a 11.5 to one compression with the cylinder block dilated by 0.5mm and truncated by 6mm due from 99 to 93 mm.

The eventual result is an estimated energy of 310hp on 91-octane fuel purchased at the gas station, with a potential output of up to 330 Hp on E85.

Good day! I know this is kinda off topic but I was wondering which blog platform are you using for this site? I’m getting sick and tired of WordPress because I’ve had issues with hackers and I’m looking at options for another platform. I would be fantastic if you could point me in the direction of a good platform.

I do not even know how I ended up here but I thought this post was great I dont know who you are but definitely youre going to a famous blogger if you arent already Cheers