Revolutionary Hydrogen Fuel Cells Now in Production: Stronger, Longer-Lasting, and Affordable

Honda and General Motors have now started manufacturing their new generation of hydrogen fuel cell systems, and the eagerly anticipated hydrogen-powered version of the CR-V is still set to be released later this year. This vehicle will be the only one of its kind to be produced in the United States, though its official name has yet to be revealed. It is speculated that it will fit into the same category as the traditional and hybrid models of the Honda CR-V, but there is also the potential for a completely unique offering.

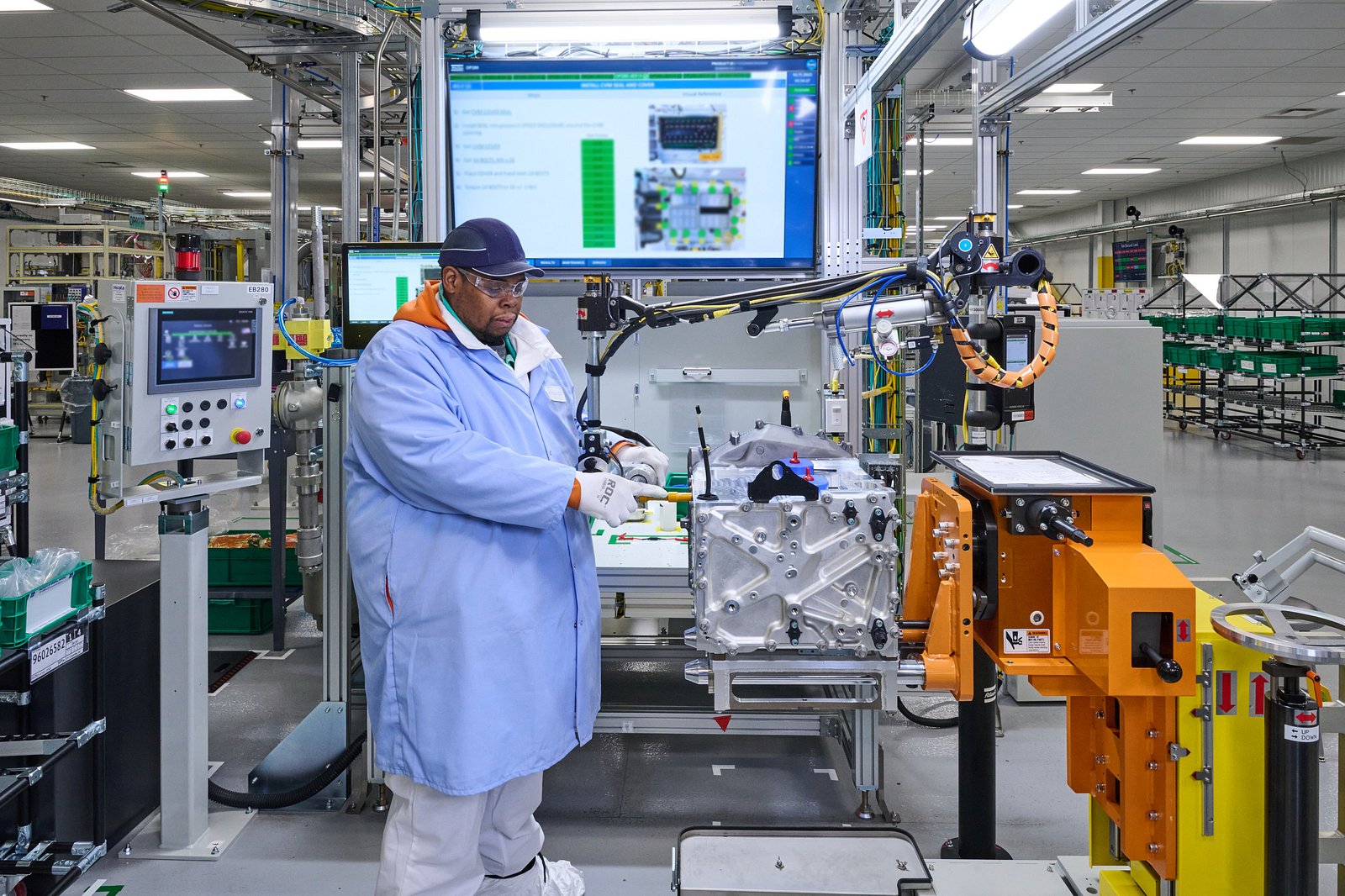

Even though the FCEV will be constructed at the Acura NSX manufacturing plant located in Ohio, the assembly of the next-generation hydrogen fuel cell systems occurs at Honda-GM’s collaborative production plant known as Fuel Cell System Manufacturing LLC (FCSM), which was established in 2017 in Brownstown, Michigan. As stated by the Japanese car company, FCSM has successfully generated employment for 80 individuals.

“Today marks a momentous occasion for the industry, as GM and Honda embark on their joint venture to manufacture full fuel cell systems at a large scale for various transportation purposes and beyond,” stated Suheb Haq, the president of FCSM. “This partnership is in line with our goal of producing top-notch, long-lasting, and cost-effective hydrogen fuel cell systems to cater to a diverse range of customers and applications.”

In 2013, the automaker began the collaborative development of an updated fuel cell system for their next generation vehicles. This venture was initiated five years after the introduction of the first-generation Clarity, as the company aimed to lead the way in promoting this type of powertrain. Unfortunately, issues with infrastructure hindered the success of this initial Clarity model, but times are changing.

Significantly, Honda has implemented upgrades in various aspects.

The primary goal of the company was to decrease the expenses associated with development and production, with the aim of tackling the steep price that deters potential buyers from investing in a hydrogen car. This objective is achievable through the implementation of strategies such as “capitalizing on economies of scale, enhancing cell design, streamlining auxiliary equipment, utilizing shared sourcing, and minimizing the reliance on expensive precious metals.”

Consequently, the upcoming fuel cell systems will be 33% more cost-effective in comparison to the recently discontinued 2019 Honda Clarity Fuel Cell.

Alongside its reduced price, the latest technology guarantees enhanced functionality and doubled longevity in comparison to its previous version. Consequently, regardless of its final design, the upcoming FCEV is expected to surpass all past models in terms of sustainability.

Honda has teamed up with Isuzu to incorporate hydrogen technology into their commercial vehicles. As a crucial aspect of their latest fuel cell system, this collaboration includes four main categories: FCEVs (vehicles), power facilities, and building equipment. The expertise gained from these endeavors contributes to heightened productivity and decreased expenditures.

Honda has been collaborating with various organizations to create hydrogen infrastructures, such as the Japan Hydrogen Station Network Joint Company in Japan and FirstElement Fuel in North America. Furthermore, the manufacturer is also advancing technology to aid in sustaining life in outer space.

According to Tetsuo Suzuki, vice president of FCSM, “We have implemented a mass production mindset while also prioritizing attention to detail and a commitment to producing high-quality products. As a result, we are fully prepared to cater to the evolving demands of customers in the future, particularly in regards to fuel cell technology and the emerging hydrogen era.”

Honda aims to sell 2,000 units per year of their newly developed fuel cell system. At the same time, they have revealed the pricing for their all-electric model, the Honda Prologue, as hydrogen production begins. These measures are part of the brand’s efforts to support their zero-tailpipe emission campaign.

Very interesting topic, thanks for posting.Raise your business