Building the Nissan GT-R50 with ItalDesign

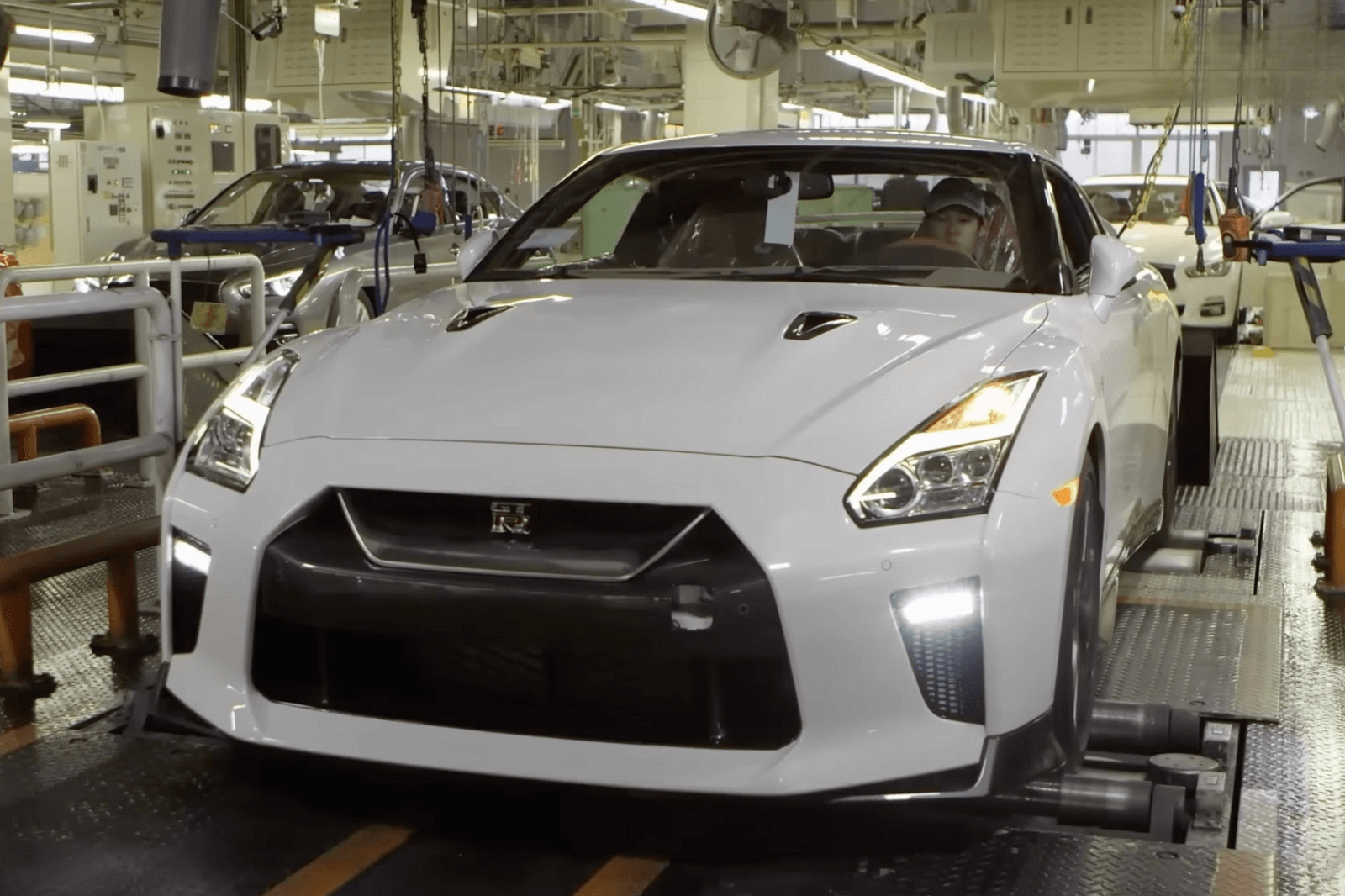

Without a doubt, the Nissan GT-R is one of Japan’s most renowned nameplates. But before the performance car is released to its adoring public, Nissan’s Tochigi Plant exhaustively conforms to the highest quality standards to ensure that every model is impeccable for driving on either public highways or racing circuits.

The manufacturer is generating Godzilla, with a revamp for the 2024 version. The recently unveiled GT-R has been provided with restructured bodywork to maximize aerodynamic efficiency. As components are being fitted, staff make use of fender guards to safeguard the car’s shell.

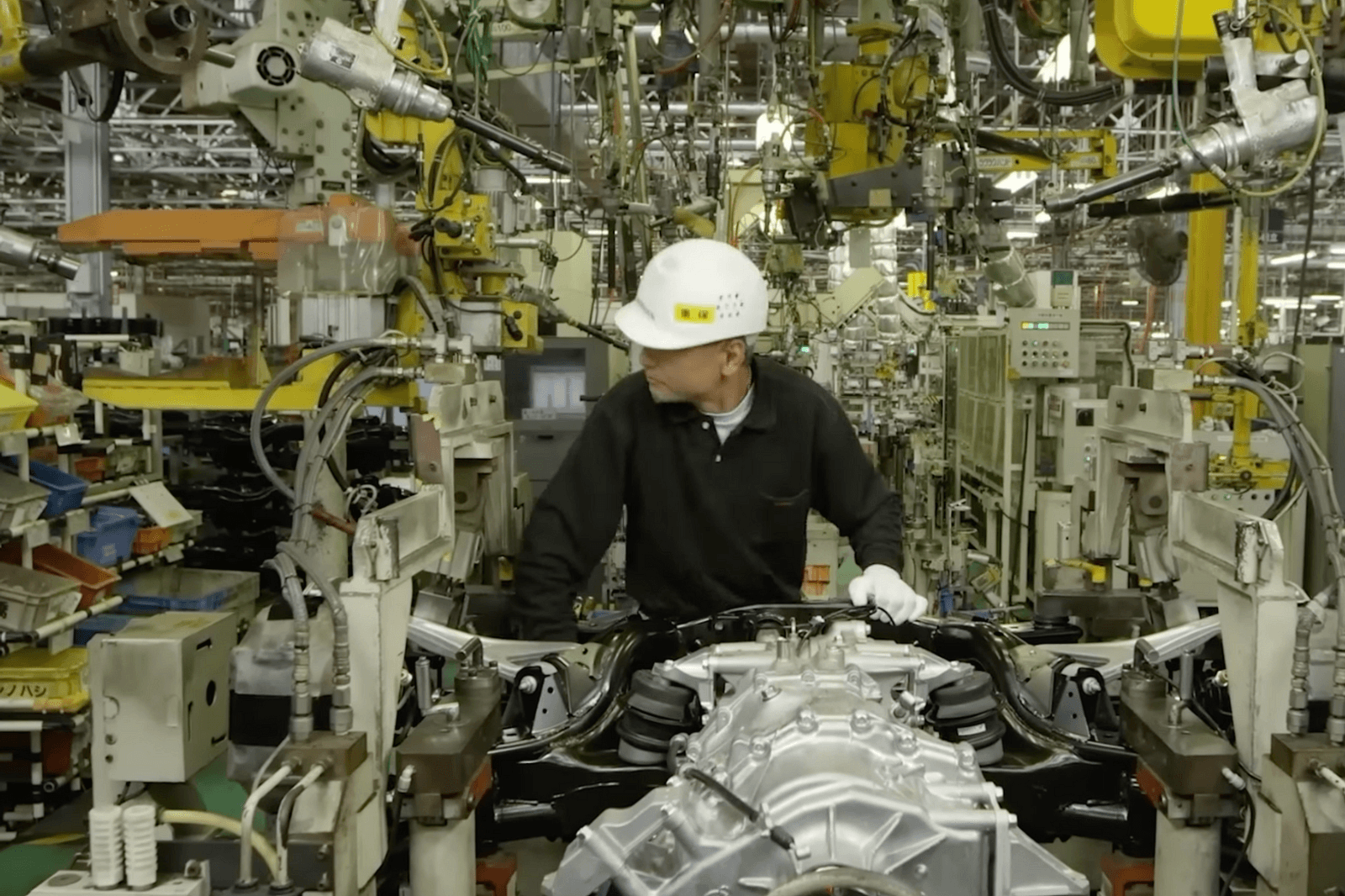

In the engine bay, the block is fabricated from die-cast aluminum putting a sturdy forged steel crankshaft and aluminum pistons into action. A hydraulic torque wrench is used to guarantee the nuts are secured to a distinguished torque level, while feeler gauges are utilized for examining the spaces between segments.

A dynamometer assessment is then carried out to assess power and torque creation at various velocities. To bring up, the US-spec Nissan GT-R is powered by a 3.8-liter twin-turbocharged V6 giving 565 horse power and 467 pound-feet of torque. On the other hand, the GT-R Nismo sports an upgraded mill that generates 600 horses and 481 pound-feet of torque.

When the majority of components are affixed, the creation models go through a wheel positioning check. This aids to avert wearing on individual elements such as suspension over the long-term.

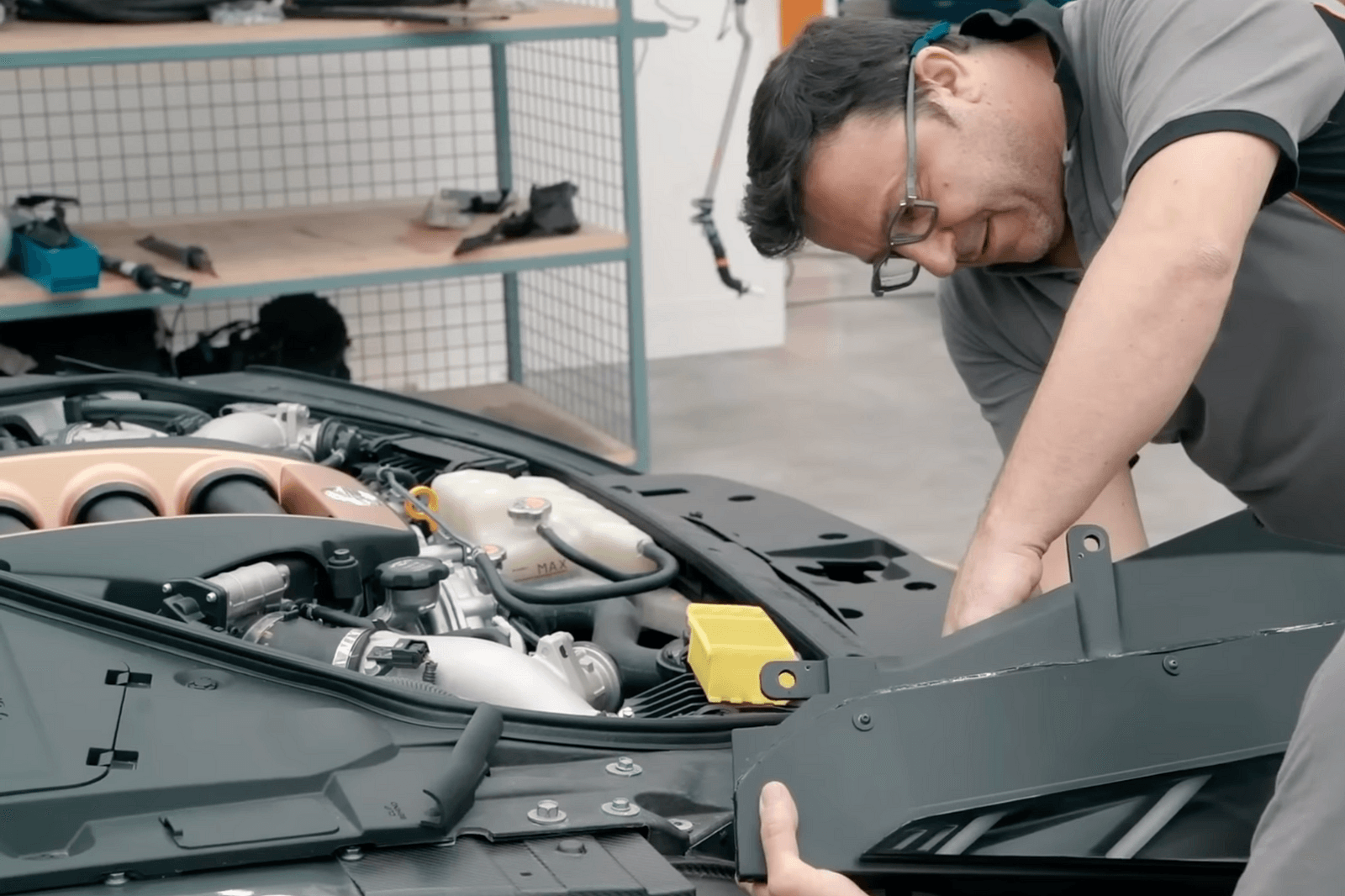

Apart from the 2024 Nissan GT-R, the factory is also producing the GT-R50 in conjunction with ItalDesign. This exclusive model was designed to pay homage to 50 years of the GT-R name brand in 2019 and ItalDesign’s anniversary in 2018.

The fabrication takes pride in crafting the GT-R50 using chisels and hammers. The cutouts on a GT-R Nismo are eliminated, particularly the C-pillar area, which is switched with fresh pieces that reduce whirling and refine aerodynamics.

Devices such as Coordinate Measuring Machines (CMMs), 3D scanners, and laser trackers are employed to guarantee accuracy in constructing the GT-R50. Computer Aided Design (CAD) and Laser Projection are also used to “ensure precise alignment and geometric accuracy.” An Eckold machine is used to aid in the hand-building process, while 3D printing is utilized for faster production of parts.

The 3.8-liter twin-turbo V6 hidden under the bonnet is skillfully crafted by hand, generating 720 horsepowers and 575 lb-ft of torque.

Nissan is fabricating solely 50 incarnations of the GT-R 50, which come with a speculated price tag of circa $1.1 million. In comparison, the regular GT-R has a kick-off fee of $120,990 in the United States.