Harness Porsche Power: Leaking Pistons No Problem!

CarBuzz has discovered a recent patent associated with the development of an advanced Porsche engine. The details submitted to the German Patent and Trade Mark Office signify that the widely known defect of combustion engines – blow-by – could potentially optimize efficiency. By creating a system that begins operating without any external input, it is anticipated that both weight and complexity could be minimized.

You may already be aware that racecars are equipped with a direct start system, where multiple ignitions are used to rotate the crankshaft until the engine “catches,” which is technically referred to as “when the starting torque of the internal combustion engine is exceeded [and] the starting speed of the internal combustion engine reached.”

That’s the long, shrill lens of the engine starting when a race car is aroused, and they avoid conventional starters due to elevated heft and intricacy. Even so, if direct activating is that straightforward, why not apply it on production vehicles?

This patent explains techniques for tackling this and avoiding it. We’ve come upon Porsche working on racecar engineering for vehicle engines for the second time this week.

Racecars have their motors preheated to try and guarantee an effortless instigation process, which is performed in the pits. On the other hand, street cars are unable to follow that same procedure, and this is particularly crucial for hybrids – which is what Porsche currently places emphasis on. To this date, they are looking at all viable alternatives for a hybrid 911 – something that may include a V4 set-up.

Porsche believes that if you’re behind the wheel of a hybrid, and you run out of electrical battery power, you don’t want to end up waiting while the motor gets warmed up or have to endure a lengthy ignition process once you slow down – especially if you are in an urban area that enforces charges on cars that run on combustible fuels.

Presently, an electrical starter motor is the answer; still, this always holds back some energy for ignition when it’s required again, resulting in needless additional weight that is not added to the “horsepower” of the hybrid system. Similarly, a belt-driven starter has the effect of a supercharger; although, significantly reduced. Ultimately, both variants add mass and lessen total accessible power.

Porsche believes that if you are able to manage the combustion engine’s predisposition towards blow-by and restrict the pressure in each cylinder, it is possible to construct an atmosphere in which the engine would have negligible difficulty when starting. Blow-by cannot wholly leave the motor and often resides as oil residue, hydrocarbons, and nitrogen oxides in the system. Those gasses are packed with ample energy that usually goes to waste. When they leave the system, they also cause a decrease of compression. The majority of these gases can be recycled with exhaust fume recirculation, oxidized in the exhaust, or stored in filters.

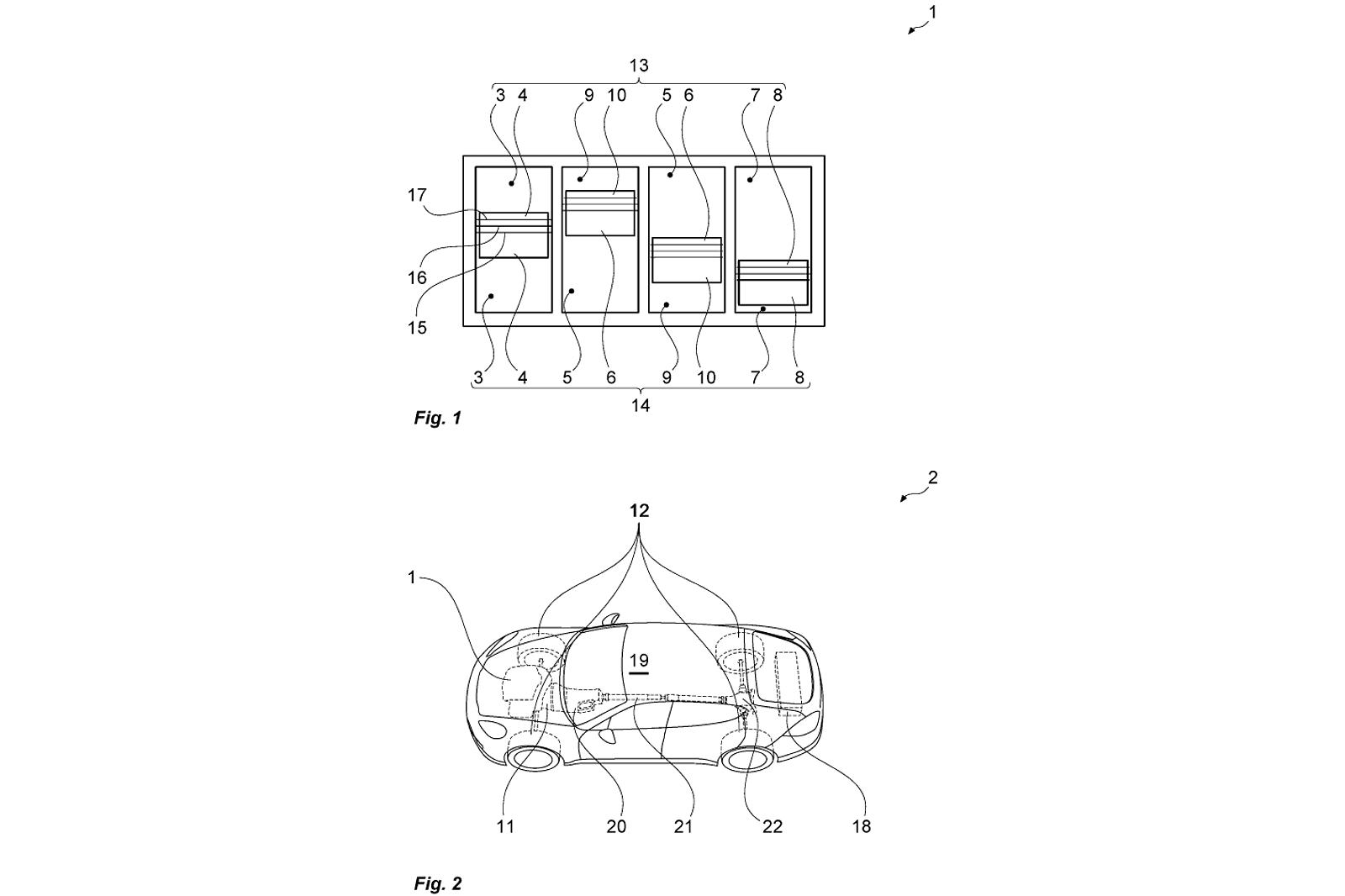

The disparity of contraction triggered by these vapours is crucial, and to optimise this, Porsche proffers varying the construction of each cylinder to lower languidness within the lighting action. Notwithstanding, this necessitates its own meticulous process, since the crankshaft cycles in thousands every minute before halting when switching off the motor. When it needs recreation, what could have initially been fired up could now be culminating, implying that the reshaped cylinder configuration wouldn’t precisely be maximally adapted.

A more interesting concept proposes the utilization of multiple temperature-sensitive gaskets on every piston that can be enlarged when a predetermined temperature is reached, and then shrink after a certain amount of ignitions have occurred within the cylinder. This allows for a larger blow-by rate, which lessens the resistance of the piston and connecting rod as they interact with the crankshaft. Furthermore, this also to some extent balances out the low viscosity character of cold oil inside the cylinder.

“When it comes to engines, Porsche notes that ‘the level of compression torque, therefore, decreases as the blow-by rate increases.’ This means that when there is a high rate of blow-by, the amount of torque generated by the engine during the compression stroke is reduced. This can lead to a decrease in engine power and efficiency, as well as increased emissions. To reduce the blow-by rate, Porsche recommends regularly changing the oil and filter, as well as using higher quality fuels and lubricants.”

Porsche seeks to take advantage of this by providing the first ignition cylinder with a specific compression and elevating it for the second. This has the advantage of achieving lesser blow-by compared to the other cylinders because it capitalizes on the kinetic energy generated from the initial one. The following cylinder gets a compression that is lower than that of the second but equal or more than the very first. This trend continues until the engine kicks in, making it easier with each ignition process.

Porsche states that the blow-by would differ no more than 5% or less than 20%. So, how can they be sure of what the pressure inside each piston is and when? That’s thanks to the fixed ratio of oxygen and gasoline in a fuel/air combination – due to its infinitesimal variation, it’s an effortless calculation to establish how densely it would be in certain chamber at a precise point during a crankshaft’s turning.

Of course, Porsche understands that initiating this approach might not always be achievable, especially in harsh cold weather. Nevertheless, the starter motor (including any external electrical motor) can be much more lightweight, inexpensive, smaller and easier to use while still providing the same strength level. Moreover, starting the engine will be smoother, subsequently reducing harmful effects imposed onto the walls of the cylinder and piston rings even when the oil feels like a dense slime upon commencement.

This new technology could soon prove to be indispensable in making 911s ultra-efficient and lightweight, thus extending the life of the combustion engine.