Behind the Scenes: Batteries Production

The Ford F-150 Lightning may have the upper hand when it comes to being America’s premier electric pickup truck, however, as is the case with all other automobiles, it must start somewhere. The YouTube channel Frame has graciously decided to give people a glimpse into the inner workings of the Ford Rouge Electric Vehicle Center for an in-depth look at the production and assembly process of this amazing model.

The establishment located in Dearborn, Michigan is the EV-devoted factory of Blue Oval. In spite of the downturn in sales for F-150 Lightning resulting from considerable rate hikes, the manufacturing unit continues to strive so that Ford is prepared when wanting for its products boosts yet again.

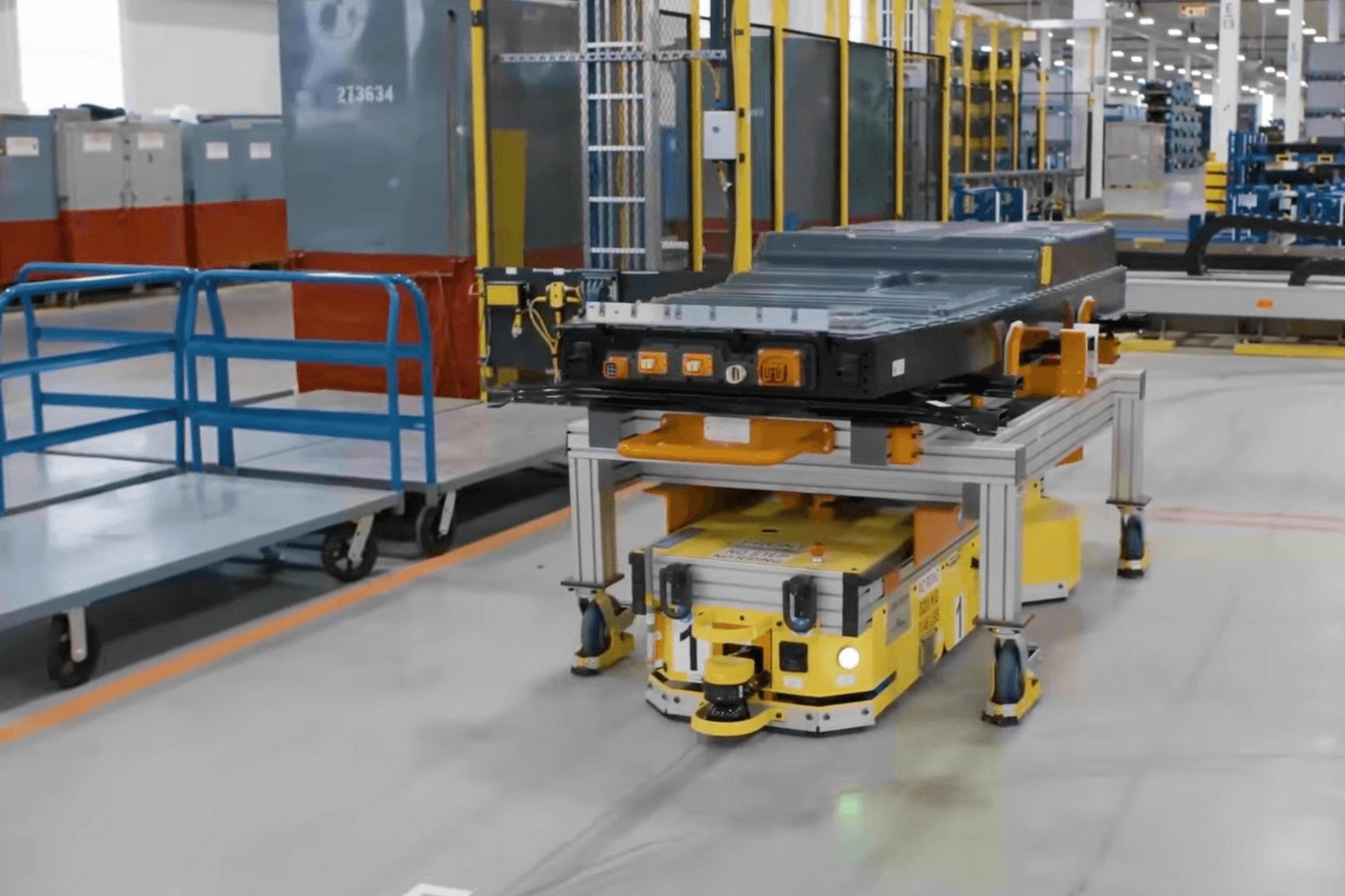

Robotic guided carriages (AGVs) convey the assemblage components from point to point across the production floor to varied work locations. Lifters and transporters supplement this, as certain components cannot be shifted by humans alone.

The employees have been assigned to fit numerous elements, among them the wiring rig that has to be affixed within the passenger compartment, fixed in employing fasteners, clips, and adhesive tape. Additionally, the headlights, charging port, and support bracket ought to also be positioned in the proper spot by hand with the insignias being applied utilizing exclusive adhesive.

A specialised jig is deployed in order to integrate the dashboard, comprising of components such as the steering wheel and infotainment display, into the auto’s interior. Accomplishing this necessitates that levellers be used during the body build phase to affix the compartment and pickup bed.

Renishaw CMM Machines are adopted to examine stator pieces for surface blemishes or irregularities. This device further assists in confirming geometric dimensioning and tolerancing (GD&T) on the stator components while the rotor is adjusted by adding and subtracting mass. Employees also undertake voltage gauging to verify that the appropriate voltage is furnished to the engine according to its criteria.

Once the construction has been finished, the vehicles are driven onto Comau Load Cells so as to calculate their cargo carrying capabilities. The Ford F-150 Lightning presents a load capacity of 2,235 pounds, surpassing that of the Rivian R1T’s 1,760 lbs but not equaling the Tesla Cybertruck’s own capability of 2,500 pounds.

The fabrication of the Ford F-150 Lightning is set to be enhanced with a $3.5 billion battery facility located in Marshall, Michigan, which was at first projected to be operational by 2026. It is intended to make Ford’s electric automobiles, such as the F-150 Lightning, more cost-effective, potentially providing the model with a much-needed boost in sales. But last month, Ford declared that they are now reevaluating this plan.

I adore assembling useful info, this post has got me even more info! .

I’m also relieved of thee constant want to eatFeeel free too visit my blog post; garlandlieb3Wordpresscom