One Piece Mfg Through Tesla-Inspired Advances.

Toyota recently presented a display of its upgraded production approaches to reporters at its Myochi factory. During the event, they unveiled the information on how embracing an adaptation of Tesla’s gigapress casting method has noticeably decreased the production time for their cars. As reported by Nikkei Asia, blazing-hot liquid metal is funneled into a mold and promptly cools from about 650 degrees Celsius down to about 250° C.

Composing an integral portion of the rear framework of the car, this one-piece devise creates a form that typically necessitates the coalescence of 86 parts in 33 steps. This approach clearly streamlines production, reducing the hours of laborious manual work to merely three minutes! Toyota has embraced the idea wholeheartedly and is by no means the only company to do so.

Hyundai is examining like production processes, and Volkswagen is even gaining knowledge from Tesla. Any mainstream maker wanting to advance efficacy ought to examine the process that Tesla initially instituted; Toyota is aiming for a 50% cutback in output proceedings, facility investment, plus lead time required for preparation. Gigacasting is only one part of accomplishing that objective.

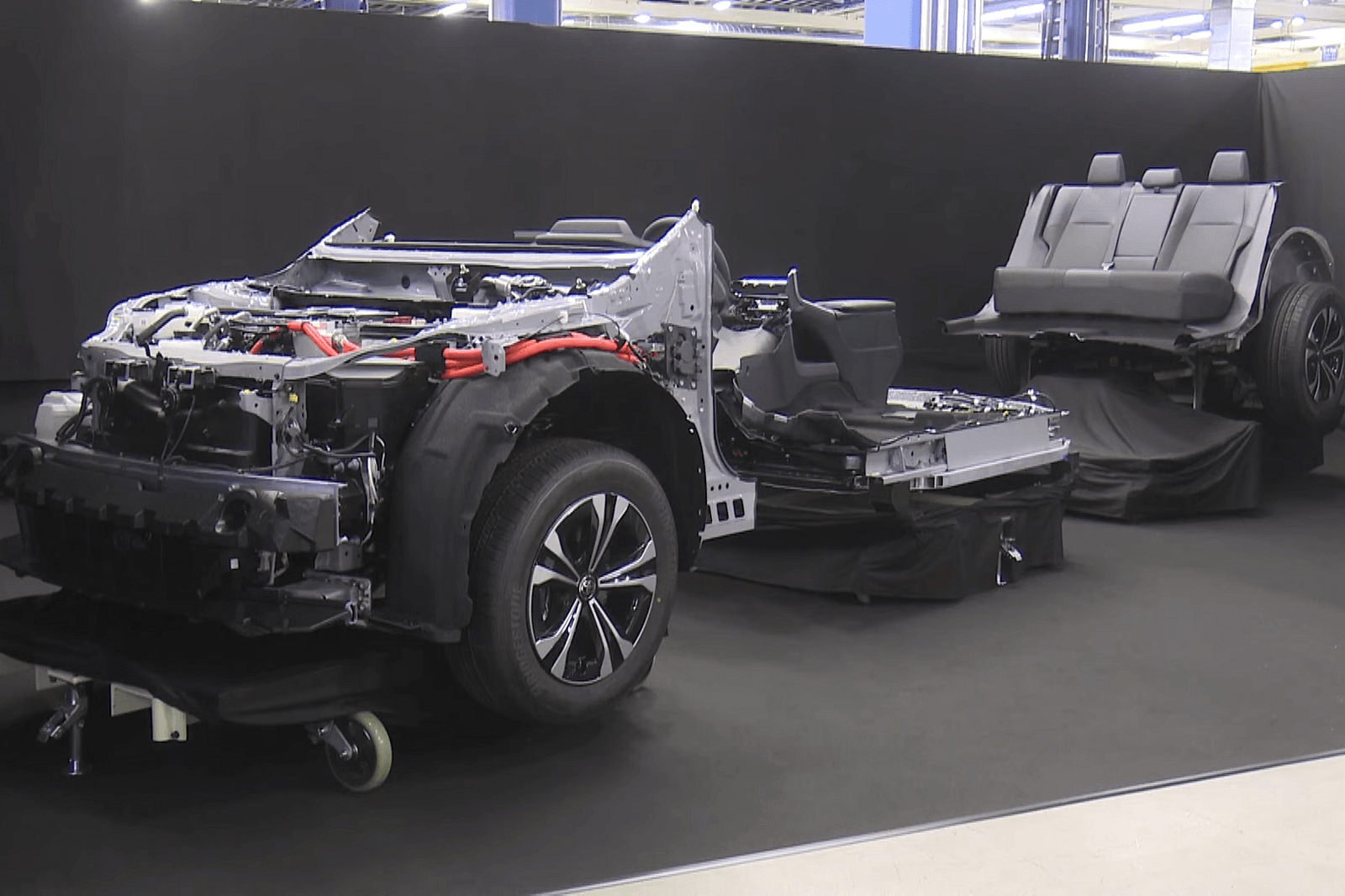

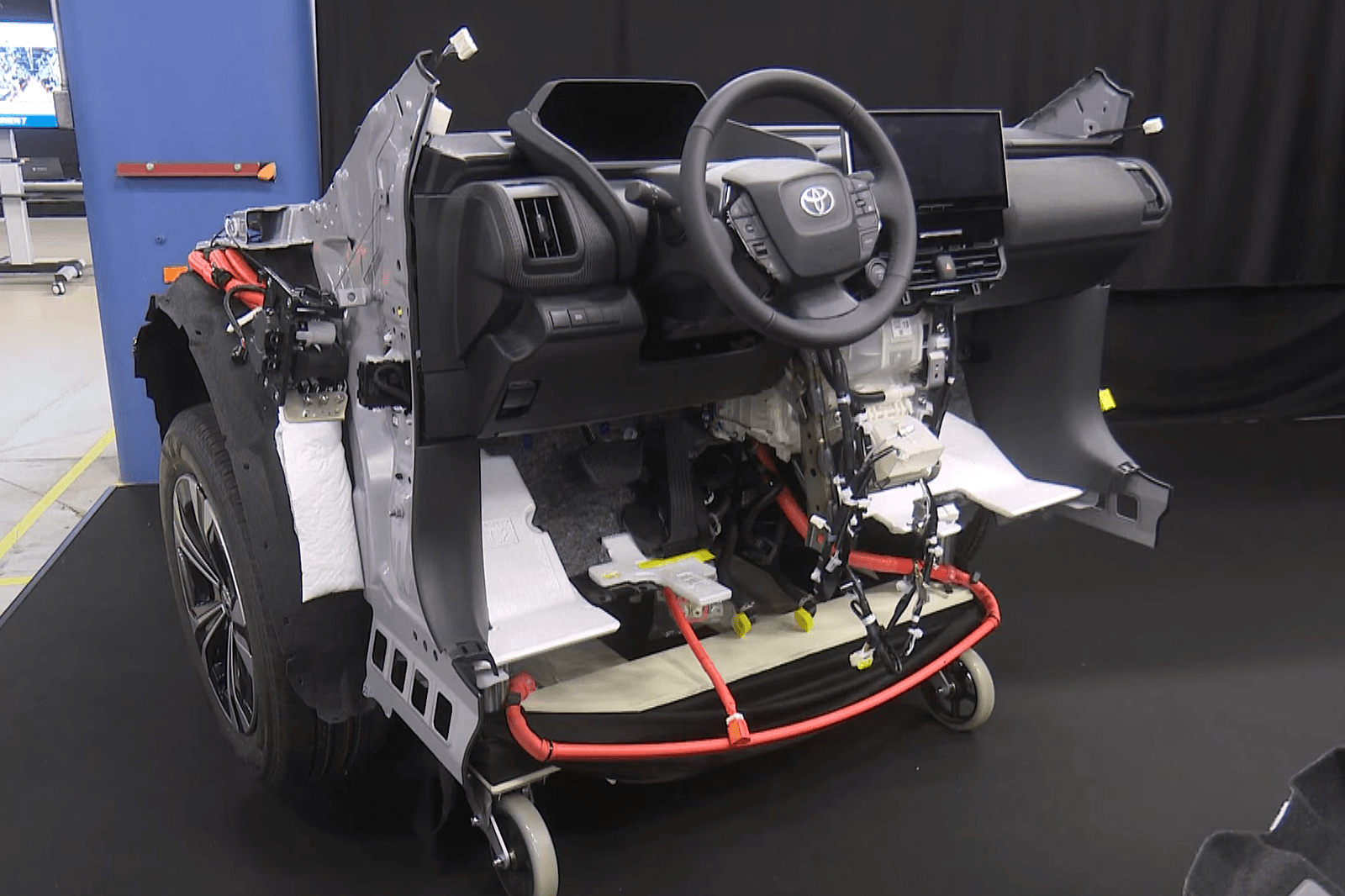

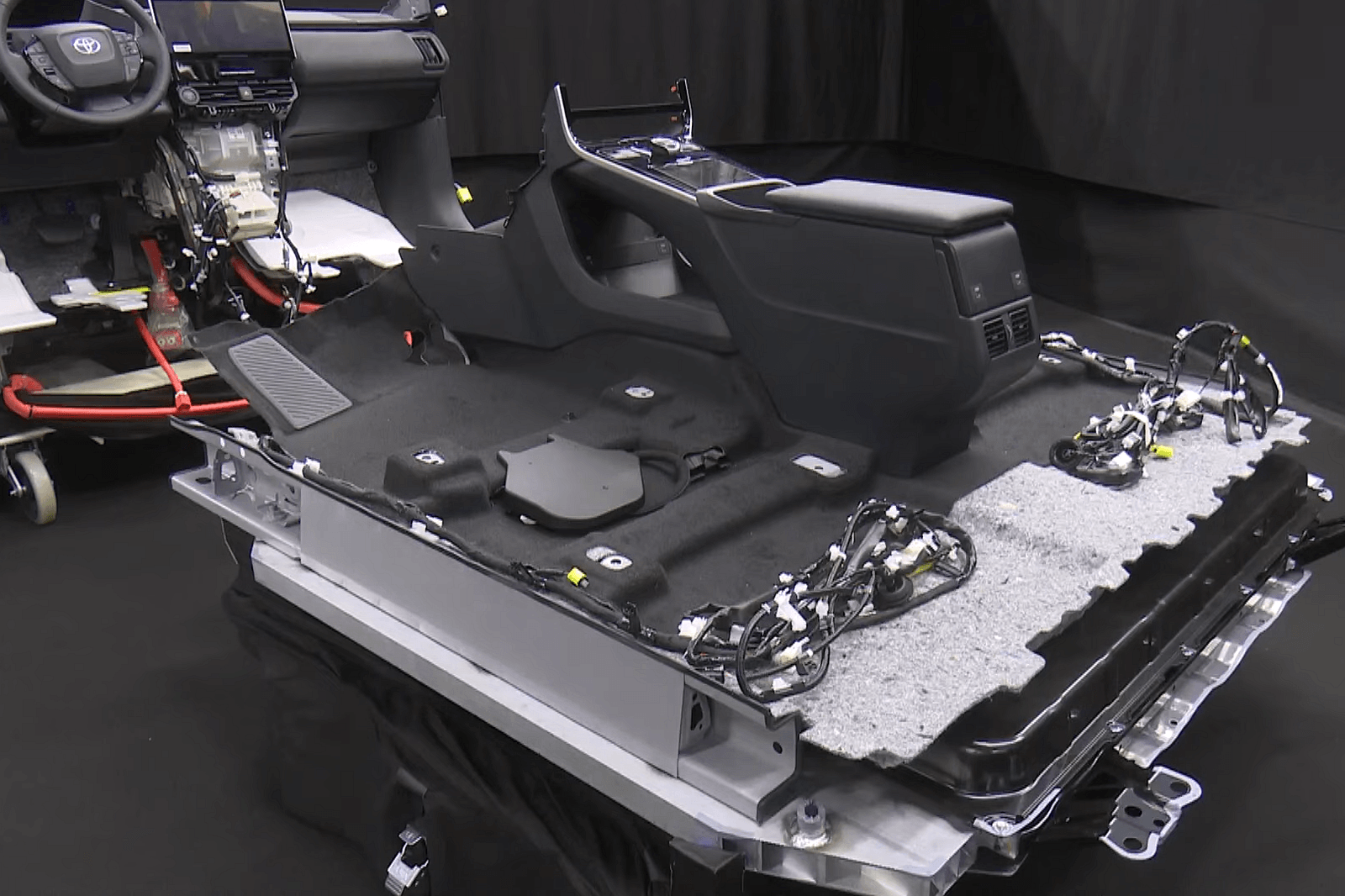

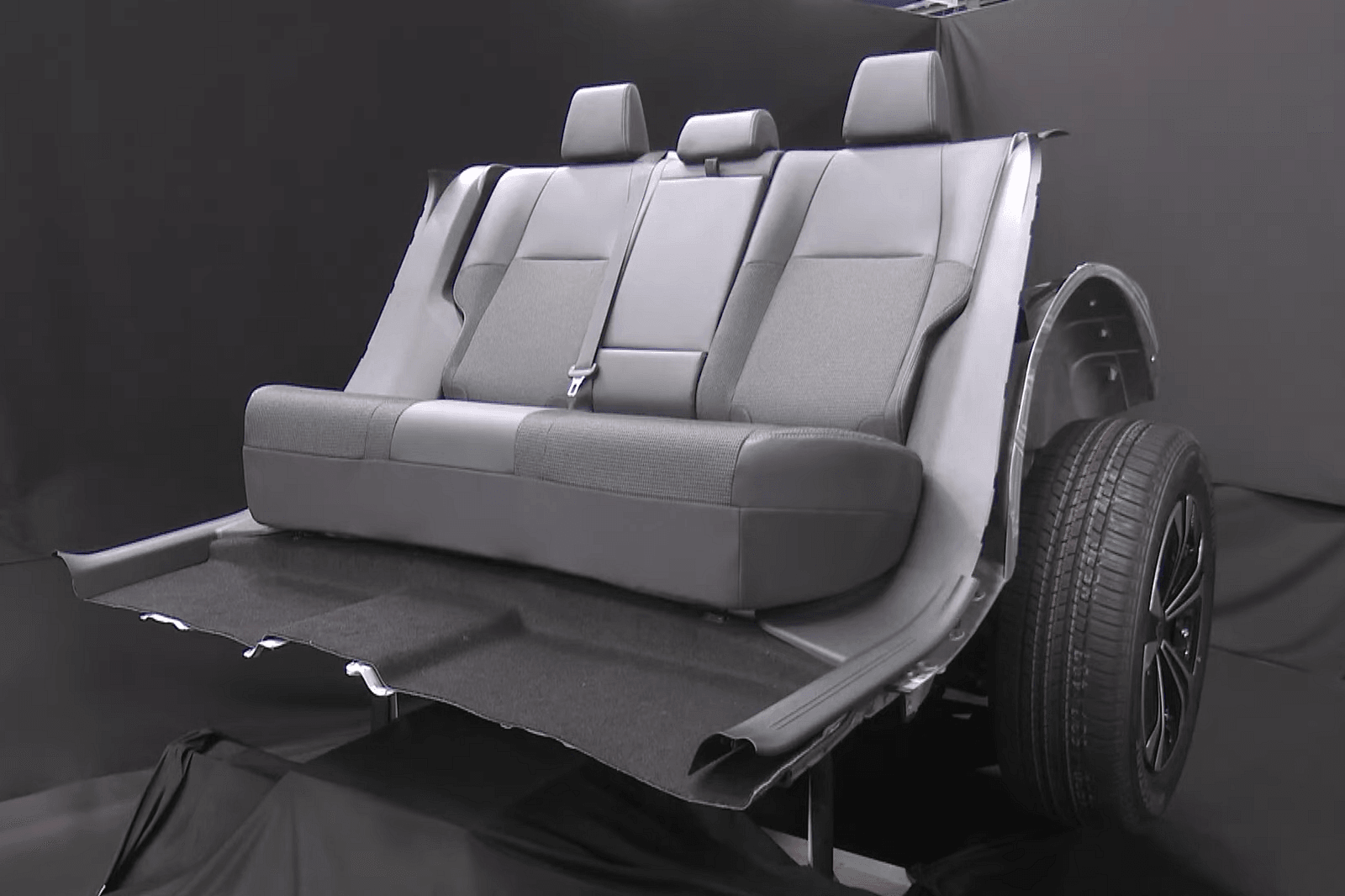

Toyota recently demonstrated the self-sufficient production capabilities of its Motomachi facility, displaying a car – similar to the bZ4x design – with missing external elements, and slowly traveling at a snail-like pace (0.1m/s) towards an automated arm which fits the seats in place before it moves on for assessment and shipment. This approach eliminates the necessity for conveyor belts and is particularly significant for a maker with such varied models.

The remarkable decrease in area and efficiency – regardless of the exact car model being manufactured – will be impressive. Toyota has an ambition to reduce assembly time to five hours, which is half of the amount it was before.

This world-first advance in efficacy is critical to Toyota’s plan of offering 3.5 million electric motors by 2030 – 60fold the number they marketed in 2020. Toyota is already hefting the advantage over emerging battery methods and possesses a vast mound of patents concerning solid-state technologies that will maintain its hold on the next few years and beyond. The first EV to take gain from this modernized heirarchy and mechanisms is ready to launch in 2026, but we will get an impression about what can come when it is shown as a concept during upcoming month.

Toyota acknowledges that companies such as Tesla should be taken into account when it comes to innovation. “We are learning from the expertise of EV manufacturers to face the challenge of producing 3.5 million EVs by 2030,” said Kazuaki Shingo, the Chief Production Officer.

With the interim, Tesla is elevating their gigapress concept to a further extent to defend their stature as the highest-grossing electric vehicle maker globally.