Mass Production: A Troublesome Issue

Volkswagen AG revealed that the trial of a newly developed solid-state battery proved immensely successful, exceeding industry expectations. This battery was designed by QuantumScape Corporation based in California and tested at the VW operated power unit PowerCo. In the previous year 2018, Volkswagen and QuantumScape formed a partnership with the German carmaker becoming the leading investor and client of the other.

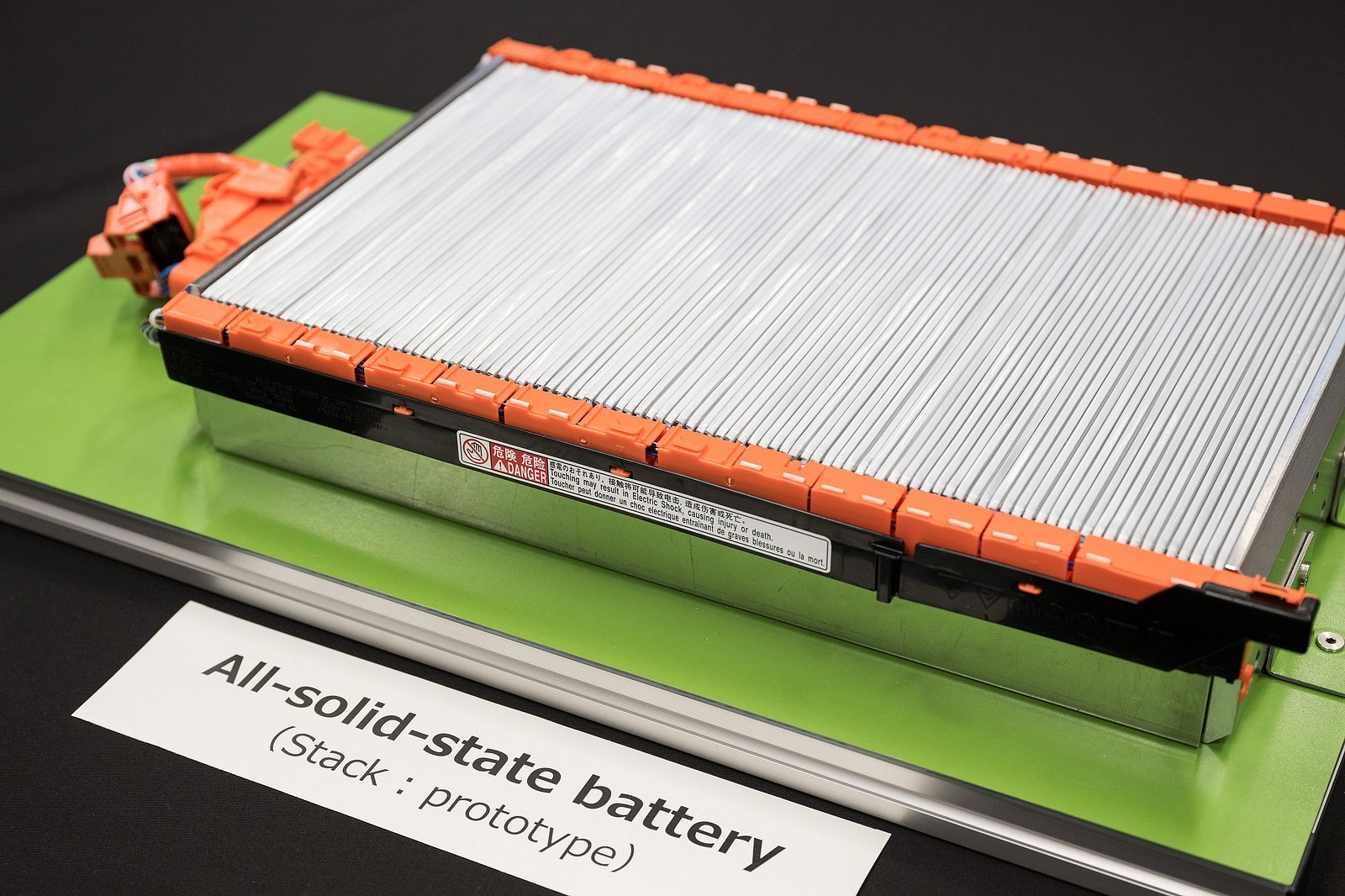

Solid-state batteries are often viewed as the subsequent noteworthy stride in electromobility, therefore Volkswagen’s research and development on this matter is exceptionally crucial.

Volkswagen put their pioneering battery technology to the test and the outcomes were astonishing. PowerCo tested the battery pack with over 1,000 charging cycles, equating to roughly 310,685 miles of use. After finishing the examination, there was merely a 5% decrease in its storage capacity – hugely exceeding industry specs which is usually 20% after 700 charging cycles.

“The results we’ve seen are quite encouraging and really demonstrate the potential of the solid-state cell,” commented Frank Blome, CEO of PowerCo. “We believe that this could ultimately lead to a battery cell with long ranges, rapid charging capabilities, and very little degradation over time. We remain committed to the solid-state cell and are working diligently alongside our partner QuantumScape to bring it into mass production.”

In brief, this product brutally stands up to all the critiques usually cast upon electric cars and in excess. Thusly, it’s not unexpected that QuantumScape would like to rapidly get the battery cell to consumers. However, that is easier said than done which is why QuantumScape has curved its emphasis towards batteries for personal electronics. A company investment letter unveiled this key detail as reported by Automotive News.

Toyota has made a shift in investment to a friendlier collaboration with Idemitsu Kosan Co., and their cooperation has already brought forth a prototype of a solid-state battery. This will go far in assisting them in putting Toyota on track to fulfill its initial goal of possessing a 600-mile range and having a recharge time of merely 10 minutes by 2027. Toyota, boasting more patents related to solid-state batteries than any other business, will surely gain from this union.

Toyota is targeting an impressive 600 miles of range, whereas Volkswagen undertook examinations employing a hypothetical vehicle with a WLTP scope between 500-600 kilometers, which converts to roughly 312.5 – 375 miles. It’s definitely an intriguing comparison. Toyota has its sights set on extensive range while VW prefers less, thus inevitably expediting the charging process. If Toyota is able to acquire 600 miles in 10 minutes, it’s hypothesized Volkswagen should have the capability to accomplish the above mileage in half that time. This would be a formidable selling point for the imminent ID.4.

Several corporations are seeking to progress solid-state technology, yet it remains a mysterious challenge. Nissan aired that its advanced system will debut in 2028. There were not any particulars made available, however the carmaker did emphasize that charging times would be accelerated threefold and two distinctive battery sizes would be accessible. The light one is adapted for cars such as the Leaf and the stronger one for potential electric versions of the Titan or the other pickup trucks from the Renault/Nissan/Mitsubishi Alliance.

BMW has declared that their solid-state battery technology will not be available until 2030. It had been anticipated to make its debut with the new Neue Klasse EVs, but mass production won’t become plausible until the start of the coming decade.

Toyota has been forced to retract since their disclosure, admitting that mass-producing EVs will not occur until the year 2030. Besides Honda, who claims this innovation is fundamental for the cost reduction of these vehicles, it looks like all car makers are facing complications when it comes to developing production.

This fresh progression could possibly put Volkswagen at the head of the charge, though without an exact release date established, we can just make a smart conject. We’re cognizant of VW’s upcoming Scalable Systems Platform (SSP) launching earlier than anticipated and that the firm is making a $2 billion fabricating and battery plant in South Carolina. Car construction will not get up and running until 2026, leaving us to ask if the plant can manufacture in bulk QuantumScape’s solid-state batteries.

As per Volkswagen, the solid-state cell they conducted experiments with integrates 24 layers, implying that its design already concurs with the projected series cell. This implies that this can be inserted into any vehicle created on the SSP platform, inclusive the two Scout models that would be showcased this year, along with the brand-new Porsche Cayenne and the Audi RS e-tron GT’s successor.

Unfortunately, the next step is still to “perfect and scale the manufacturing processes”, a feat that many other companies are still struggling with. To reach this goal, companies must invest in the latest technologies, such as automation and robotics, to ensure that their processes are both efficient and accurate. Additionally, they should also focus on improving their quality assurance systems, which can help them identify and address any potential issues early on. Finally, they should look into ways to streamline their operations, such as using advanced analytics and predictive modeling, to ensure that their products are manufactured in the most cost-effective manner possible.