Changes at the Sant’Agata Bolognese Facility

In honor of Lamborghini’s 60th anniversary, the Sant’Agata Bolognese facility is recognizing six decades of car manufacturing. To mark this milestone, the firm is investigating the evolution of the factory, from its early days through all of its modifications, leading to the creation of some of the swiftest and grandest vehicles on the planet.

The firm has commenced the jubilations for this year with a refurbishment of the Lamborghini museum, showrooms in the US and setting a new Guiness World Record. All throughout the year, these events will remain going, up until the arrival of the Aventador’s succeeding model. As part of their appreciation to their production and send-offs, the company wants to highlight all essential characteristics and peculiarities of Lamborghinis, and what better way to accomplish that than through looking into its origin?

Ferruccio Lamborghini came into the world in Cento, Italy . His folks were marginal farmers who cultivated grapes. As he matured, he had a tendency to lean towards mechanical engineering and built up tractor and marine ventures after WWII. Achieving great wealth and being an enthusiast of swift automobiles like the Maserati 3500 GT and Ferrari 250 GT (and famously receiving refusal from Enzo Ferrari), Ferruccio chose to construct his own car label which would manufacture the sports vehicle that he felt nobody else could make for him.

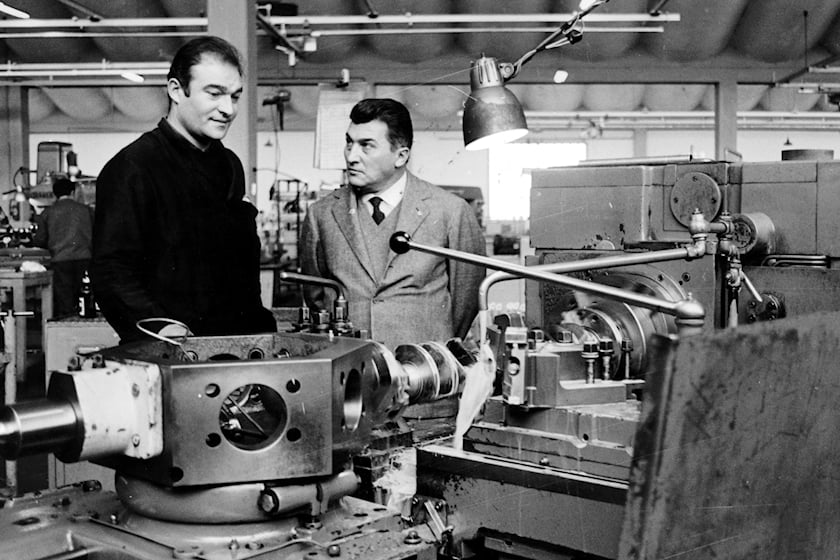

Lamborghini had been scouting for a spot to build his factory, and he finally made a decision on Sant’Agata Bolognese, which was situated in close proximity to his birthplace of Cento. Work began during the autumn of 1962 and ended with lightning speed – it only took 8 months before manufacturing was finished. By the spring of 1963, the first Lamborghini automobile rolled out: the prestigious 350 GTV prototype. And that is how the celebrated marque came into existence.

Throughout the 1960s, the facility underwent significant modifications as manufacture rose and Lamborghini wanted to ensure his vehicles were made with the most advanced technology available. The 12,000square-meter construction contained two fabrication lines, the leader’s office, sales, client service, and specialized divisions. In 1968, three fresh edifices were placed that strengthened the manufacturing capabilities and research services. Production amounts escalated during this period with the firm fabricating 67 motorcars in 1965, eventually escalating to 425 by 1971.

The 70s were a difficult era for the brand yet this difficulty was compensated by plentiful technological advances in the 80s and 90s. The marking of carbon fiber, popularized today in most sports cars, began during the mid-80s with the Countach Evoluzione that initiated the construction of a facility. During the 90s, process in research and development concerning electronics and composite systems significantly increased – something of immense necessity. Outcome of all these endeavors resulted in the absorption of the brand into the Audi group in 1998 and enlargement of production on an even greater scale.

In the year 2000, 296 automobiles were crafted, and 440 individuals were hired by the firm. At the same time, a plethora of renovations concluded at the head office, along with the construction of a museum. With an additional Centro Stile, higher customer satisfaction ensued, as well as a major rise in the automotive series and the maritime sector. Reaching 1,305 units manufactured by 2003, with 624 workers, output increased even more to 2,087 cars in the subsequent year.

Over the future period, Lamborghini Park, a prototype building and various other endeavours that concluded with the CO2-neutral certification of the plant in 2015 were established by the illustrious supercar producer. Unveiling the Urus, one of the broadest developments in quite some time was carried out, involving construction of a plant specifically intended to produce Urus alongside introducing a new test circuit with 13 distinctive surfaces.

The company has always been focused on their carbon footprint, implementing multiple strategies such as adding trigeneration plants and receiving materials by rail. This system has achieved a reduction of 85% in CO2 emissions.

Since the start, the brand has shifted from a 12,000 m2 work area to an enormous one at 160,000 m2. The transition has been noticeable, evolving from a struggling automotive manufacturer aiming to secure an investor to achieve greater earnings than any of its opponents in 2022. Soon, all products will be electrified, ushering in a novel era that will have numerous new developments brought to the acclaimed center. To this day though, part of the original construct is still present, a representation of its everlasting cultural legacy and also a prompt to make sure it doesn’t overlook its plain origins.