Spartanburg plant to utilize robot across 3 departments in South Carolina

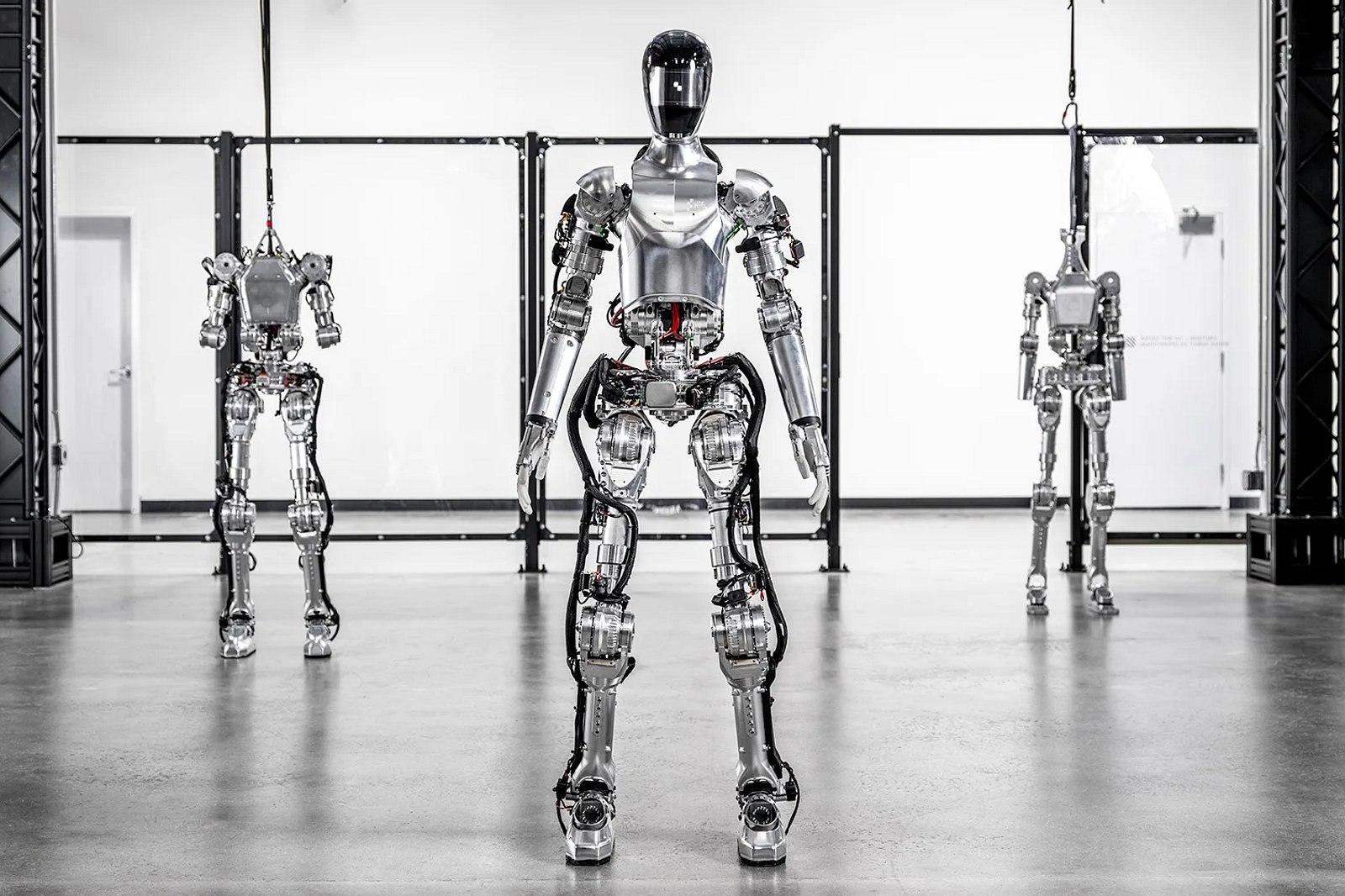

Upcoming BMW vehicles manufactured at the Spartanburg factory in South Carolina are set to be partially assembled by a humanoid robot. This advanced robot is provided by a newly established startup, Figure AI, which has recently reached an agreement with BMW Manufacturing to introduce its technology to the plant.

According to Reuters, the exact number of robots that will be utilized in the factory has not been revealed. However, the CEO of Figure, Brett Adcock, states that initial quantities will be minimal and if certain goals are achieved, greater amounts will be produced.

The use of robots in the manufacturing process is imminent, as they are expected to be integrated into various areas such as the body shop, sheet metal department, and warehouse within the next 12-24 months. Once this initial stage is completed, the robots will undergo specialized training to carry out specific tasks.

In light of recent news surrounding equipment malfunctions at various car companies and lackluster demonstrations from Tesla and its highly anticipated Optimus robot, it is understandable to approach with caution. However, Adcock assures that there is no cause for concern, stating, “We have specifically engineered the robot to ensure safety when working alongside humans. Collaborating with BMW on automation within a production plant serves as a major validation for us in this industry.”

One of the most renowned robots created by a car manufacturer is Asimo, designed by Honda. Despite being introduced as the “Advanced Step in Innovative Mobility” more than 20 years ago, it never fully made its way into practical use and ultimately retired in March of 2022 after its final demonstration.

According to the specifications, “Figure’s robot” stands at a height of 5’6″ and has a weight of 60 kilograms (132 lbs). Additionally, it has a payload capacity of 44 lbs and is capable of running for a duration of five hours.

Returning to BMW and Plant Spartanburg, the massive eight million square foot campus employs over 11,000 workers who produce various crossovers and SUVs. These include the BMW X3, X4, X5, X6, X7, and XM, in their diverse forms such as coupe and M models. As this plant focuses on highly sought-after vehicle types, it holds the title of America’s largest automotive exporter in terms of value, with shipments worth almost $9.6 billion sent globally.

A humanoid automaton may appear to be a risky venture, yet if it delivers the promised benefits as envisioned by Figure and BMW, it has the potential to revolutionize productivity and swiftness. However, there is also a possibility of minor glitches turning into major recalls, but this can only be determined through BMW’s initiative.