Producing EV in Stuttgart, Germany

For the last four years, production of the Porsche Taycan has been underway from its headquarters in Stuttgart, Germany. Set to be refreshed in 2021, Frame, a YouTube channel, offers viewers a virtual exploration of the manufacturing process.

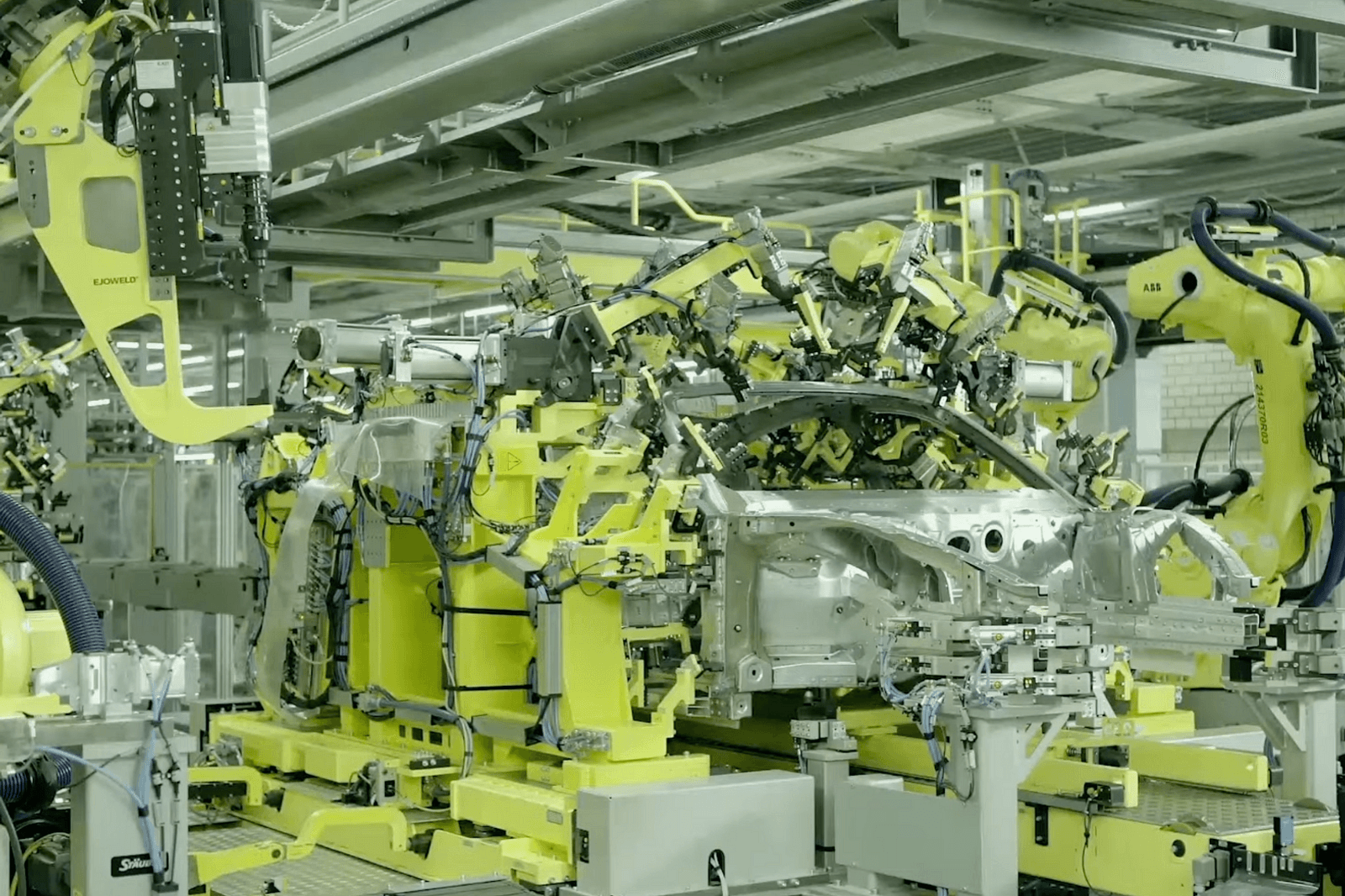

Robots capable of robotic assembly operations securely secure and bolt the various components that make up the structure of a car. Soldering is used for the smaller parts, whereas welding is done on the bigger ones; moreover, machines like these are also responsible for attaching elements such as sunroofs onto the assembly.

Inspections of the body before any painting commences take place to ensure that it is correctly fabricated. As part of the procedure, the vehicle undergoes a pretreatment procedure in an electrolytic zirconium bath. This is done for additional corrosion prevention and to help enhance how well the paint holds onto the body.

Robotic dusters clean the surface prior to painting. All units receive four coats; a preparatory layer, in addition to three pigment layers. Subsequently, operatives inspect the finished shells directly and through tactile inspection within a specially illuminated area.

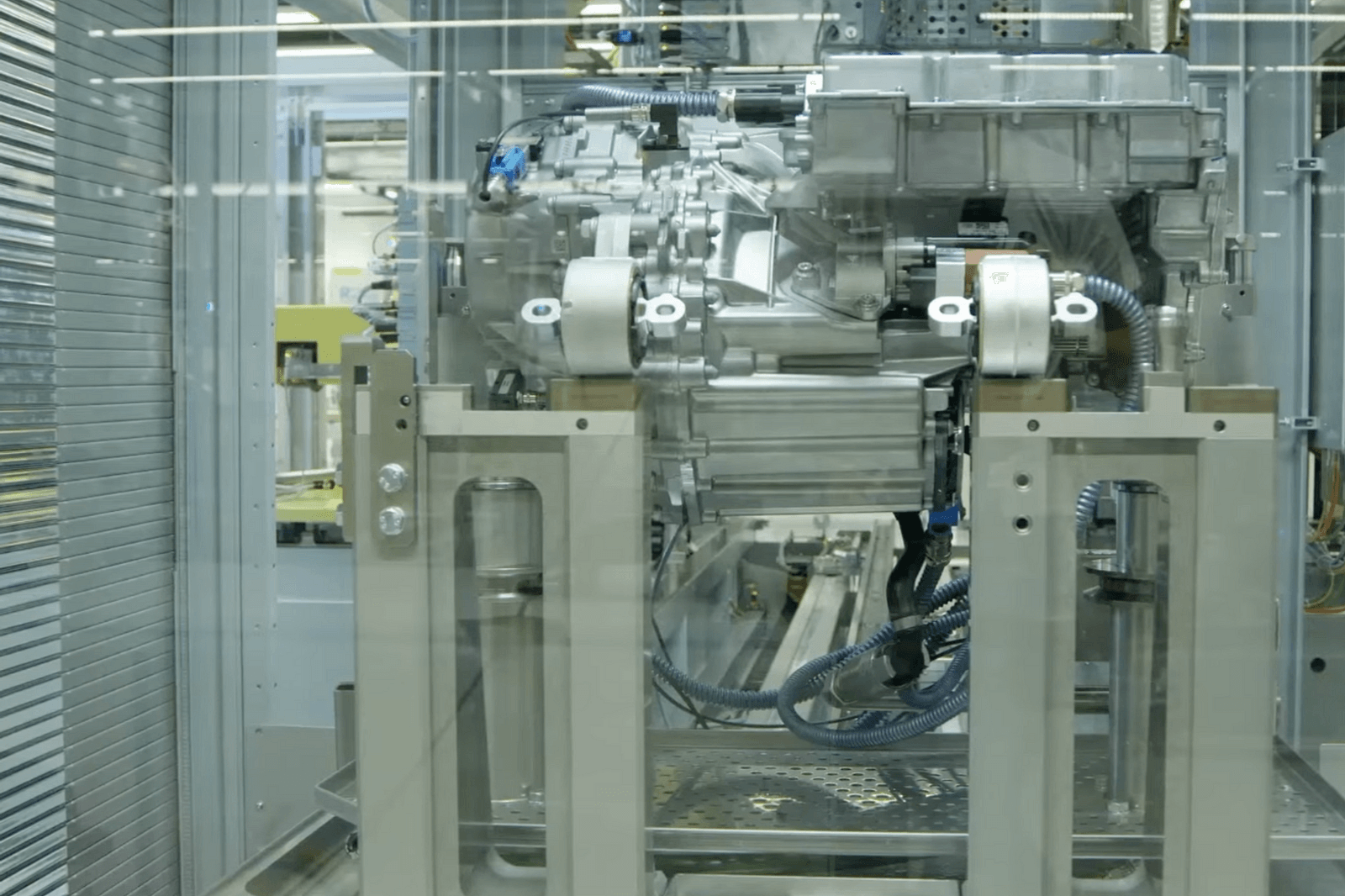

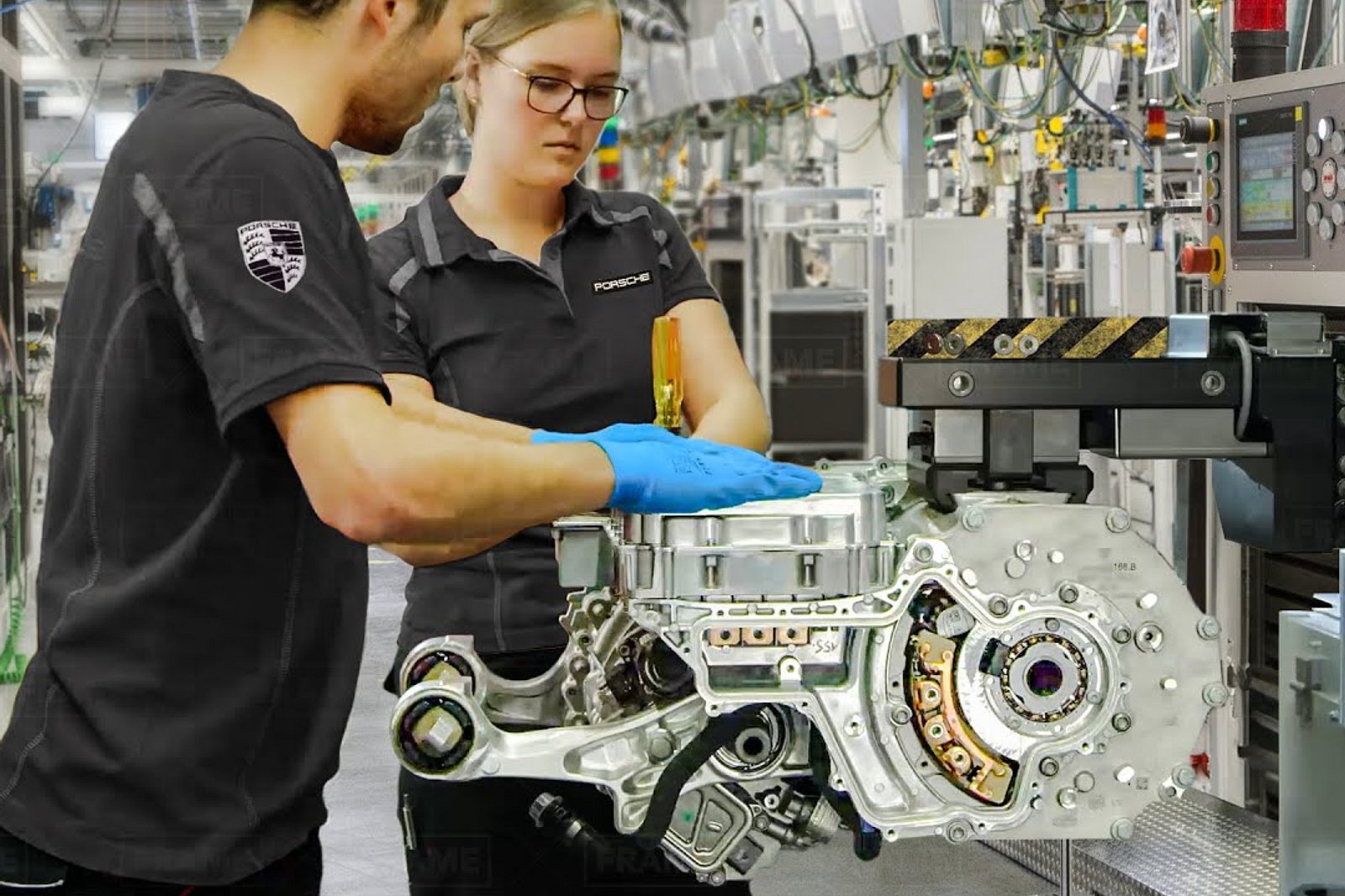

Porsche has a unique factory assigned to manufacture electric engines for its EV and hybrid fleets, comprising the Panamera E-Hybrid and the Cayenne E-Hybrid. As regards the Taycan, the EV is fitted with a synchronous motor featuring hairpin winding which comes bundled with a two-speed gearbox, a response from Porsche to tackle slow pick-up speed while travelling at high velocity. The industrial unit utilises an automated machine to transfer the powertrain to an inspecting device in order to identify any malfunctioning.

The fitting of wiring harnesses is completed by specialised professionals with the aid of robotic systems. One is a rotating structure enabling the units to revolve around for greater convenience of access to different mounting points. A designated handler is used to mount and secure the dashboard, such as the instrument cluster, safely.

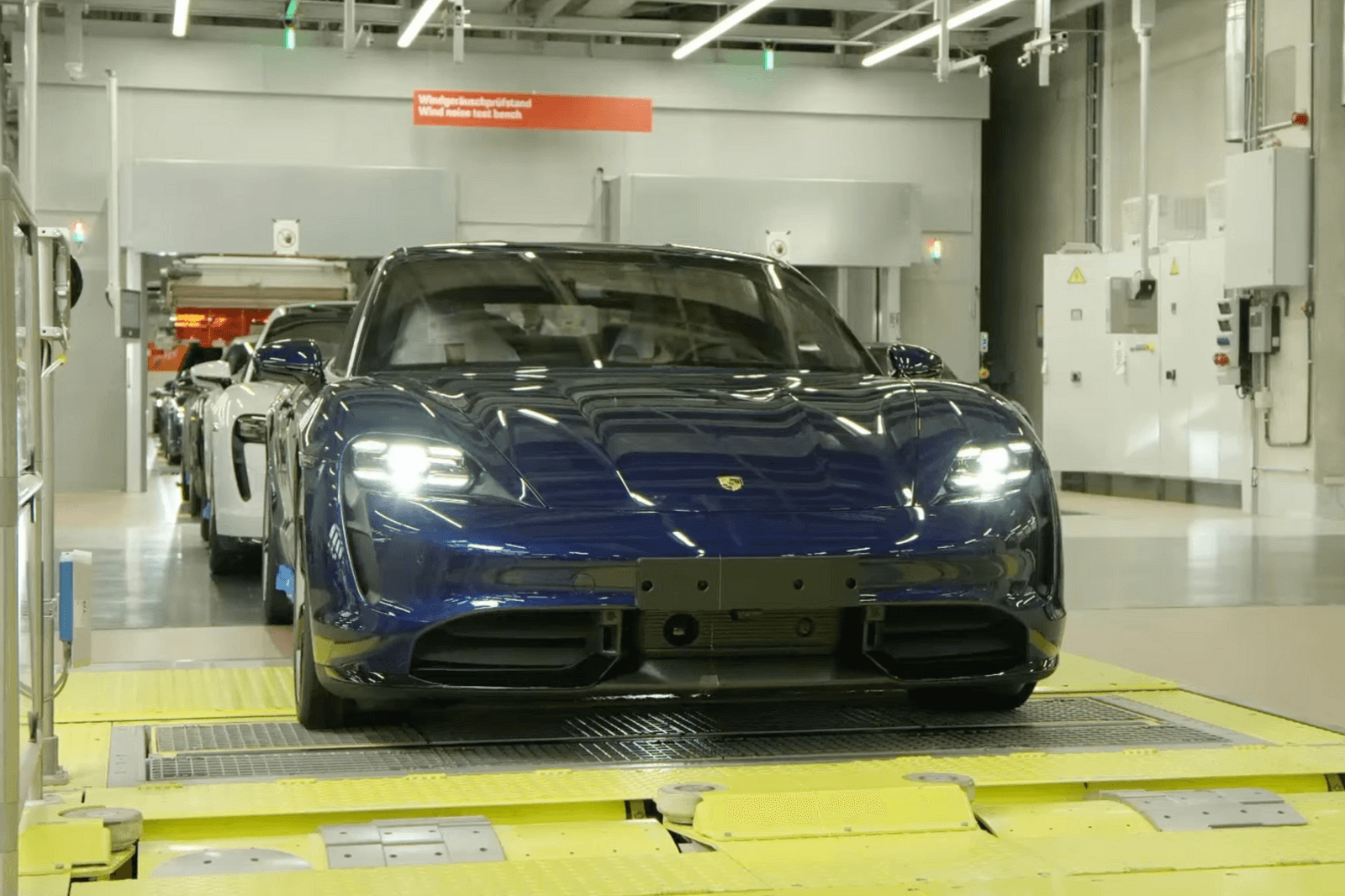

In the latter stages of fabrication, one must evaluate the product on a dynamometer and carefully observe it in a brightly illuminated tunnel to spot even minuscule deficiencies.

Porsche is striving to sustain combustion engines, however, as laid out in this manufacturing plant tour video, they are definitely not refraining from building electric cars, specifically when it comes to manufacturing them.